News

How to Use Method of Cylindrical Roller Bearings

Time:2025.01.30 Source:Roller Bearings Suppliers

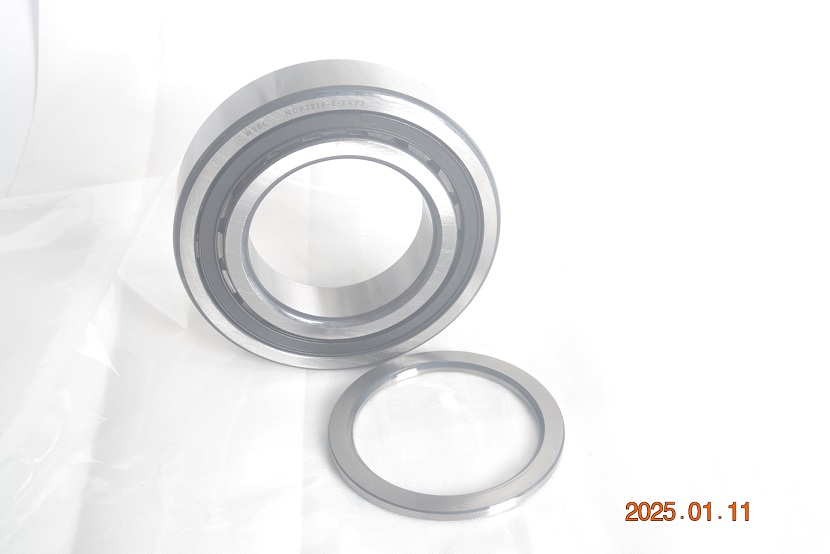

The rolling body is the centripetal rolling bearing of a cylindrical roller.The internal structure of cylindrical roller bearings adopts the roller to be arranged in parallel, and the spacer retainer or isolation block is installed between the rollers, which can prevent the inclination of the rollers or the friction between the rollers, and effectively prevent the increase of rotating torque.

Cylindrical roller and raceway for line contact bearing.Large load capacity, mainly bearing radial load.The friction between rolling body and ring retaining edge is small, suitable for high speed rotation.According to whether the ring has a side, it can be divided into NU, NJ, NUP, N, NF and other single-row cylindrical roller bearings, and NNU, NN and other double-row cylindrical roller bearings.The bearing is a detachable structure with inner and outer rings.Click here to learn more about WSBC NU313-E-TVP2

Cylindrical roller and raceway linear contact, radial load capacity is large.It is suitable for both heavy load and impact load as well as high speed rotation.

The raceway and rolling body of cylindrical roller bearing have geometric shapes.After the improved design, the bearing capacity is higher. The new structure design of the roller end face and the roller end face not only improves the axial bearing capacity of the bearing, but also improves the lubrication condition of the roller end face and the contact area of the roller end face and the roller end face.

Cylindrical roller bearings are separable bearings, which are very convenient for installation and disassembly.Cylindrical roller bearing can bear large radial load and is suitable for use in high-speed operation.

The Angle error (inclination) between the axis of the inner ring and the axis of the outer ring is very small, only 2 ~4.Therefore, the machining accuracy of the shaft and bearing pedestal is relatively high. Otherwise, uneven load or stress concentration is easy to occur at the contact part of raceway.However, the stress concentration can be reduced by modifying the roller or raceway contact bus.

Cylindrical roller bearings can be divided into single row, double row and multi - row cylindrical roller bearings according to the number of rolling body.Different structure bearing is also shown in the design of the position of the edge.The commonly used cylindrical roller bearings have the following forms:

Single row cylindrical roller bearings: Single row cylindrical roller bearings are detachable for easy installation and disassembly. Both rings can be fitted tightly. Modified contact line between roller and raceway can reduce stress concentration.Double row cylindrical roller bearings: double row cylindrical roller bearings are swimming bearings, and their separability makes it easy to install and remove.Both rings can be fitted tightly.Double row cylindrical roller bearings have almost no inclination Angle.Need WSBC NUP2218-E-TVP2,click here to learn more.

1. Bearing installation must be carried out under dry and clean environmental

conditions.Carefully check the machining quality of shaft and housing mating surfaces, shoulder ends, grooves and joint surfaces before installation.All mating surfaces must be carefully cleaned and burr removed, casting rough surfaces must be sand cleaned.

2.The bearings should be cleaned with gasoline or kerosene before installation, and used after drying, and ensure good lubrication. The bearings are generally lubricated with grease or oil.When using grease lubrication, should choose impurities, oxidation resistance, rust, extreme pressure and other properties of grease.The filling amount of grease is 30%-60% of the bearing capacity and bearing box capacity.The double row tapered roller bearing and water pump shaft bearing with sealed structure have been filled with grease, the user can use directly, and can not be cleaned again.

3.bearing installation, it must be in the ring width on the circumference of a circle of equal pressure, to press the ring into, can not use ð ¨ + top tools directly on bearing face, in order to avoid damageIn the case of a small amount of interference, but at room temperature with the sleeve pin bearing ring end face, with a ð ¨ + head banging on sleeve, through the sleeve ring is balancedIf large quantities of installation, you can use a hydraulic press.When pressing, ensure that the outer ring end face and the shell shoulder end face, the inner ring end face and the shaft shoulder end face tightly, no clearance is allowed.

4.When the interference is large, it can be installed by oil bath heating or inductor heating bearing. The heating temperature ranges from 80 °C to 100 °C, and the highest temperature cannot exceed 120°C.At the same time, tighten the bearing with a nut or other appropriate method to prevent the bearing from contracting in the direction of width after cooling and creating a gap between the ring and the shaft shoulder.

5.The clearance shall be adjusted at the end of the installation of single row tapered roller bearings.The clearance value should be determined according to different operating conditions and the magnitude of interference fit.If necessary, it shall be determined by test.The clearance of double-row tapered roller bearing and water pump shaft bearing has been adjusted before leaving the factory, and it is not necessary to adjust them during installation.

6.After the bearing is installed, a rotation test shall be carried out. First, it shall be used for the rotating shaft or bearing box.After normal operation test, it can be delivered for use.

Hot Topics

Copyright © Wuxi Spark Bearings Co.,Ltd Co., Ltd All Rights Reserved. Sitemap

www.spark-bearing.com. Profession in Roller Bearings, Ball Bearings and Taper Toller Bearings-China Suppliers.