News

Inspection Items When WSBC Bearing is in Operation

Time:2020.07.17 Source:Roller Bearings Suppliers

It is becoming more and more important to check the status of running transit and prepare a thorough inspection plan in advance.

Among them, bearing is the focus of attention, because it is the most important rotating part in all rotating machines, and condition monitoring is an important part of preventive maintenance. Bearing damage is detected early to avoid unplanned equipment downtime due to bearing damage.

In particular, bearings in important machines or in harsh environments should be checked frequently. There are quite a few systems and instruments on the market for monitoring bearings. Most of these instruments are based on vibration measurements.

However, not all instruments are equipped with these advanced instruments. In this case, the operator or maintenance engineer of the transfer machine must maintain a high degree of alertness to the "fault signal" of the bearing, such as noise, temperature and vibration.

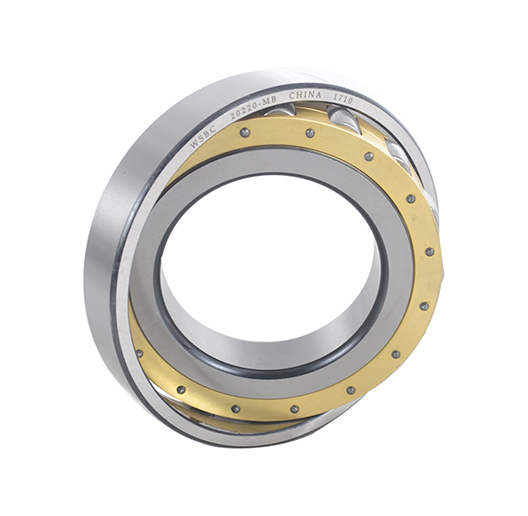

"Listening","touching" and "observing" are three important methods. Wuxi Spark Bearing Co., Ltd The views provided below can be used as your reference. Click here to learn more about WSBC 20218-MB

1. Listen

Using hearing to identify irregular operations is a very common method. For example, the use of electronic stethoscopes and mechanical styluses to detect abnormal noise of a part is often used by experienced staff. If the bearing is in good operating conditions, it will emit a low whine, and if it emits sharp hissing, squeaking, and other irregular sounds, it usually indicates that the WSBC bearing is in poor operating conditions.

The sharp creaking noise may be caused by improper lubrication, and improper bearing clearance may cause metallic noise. The dents on the outer ring of the bearing will cause vibration and cause a smooth and crisp sound. If the knocking scars caused by the installation will also produce noise, this noise will vary with the bearing speed.

If there is intermittent noise, it means that the rolling element may be damaged. This sound occurs when the damaged surface is crushed. If there are pollutants in the bearing, it often causes hissing noise. Severe WSBC bearing damage will produce irregular and huge noise.

Although the damage of WSBC bearings can be detected by hearing, but usually it has reached the stage where the bearings must be replaced immediately, so a better method is to use such as electronic condition monitoring equipment to pre-diagnose the operation of the bearings.

Compared with the old method (using a wooden stick or screwdriver against the bearing box and the other end against the ear), using advanced instruments can more accurately predict the bearing condition.

2. Touch

High temperatures often indicate that the bearing is already in an abnormal state. High temperature is also harmful to the lubricant in WSBC bearings. Sometimes overheating of the bearing can be attributed to the lubricant of the bearing. If the bearing is operated at a temperature exceeding 125°C (260°F) for a long time, it will reduce the life of the bearing.

The reasons for the high temperature of the bearing are: insufficient lubrication or excessive lubrication. The lubricant contains Impurities, excessive loads, damaged bearings, insufficient gaps, high friction caused by oil seals, etc.

Therefore, continuous monitoring of WSBC bearing temperature is necessary, whether it is to measure the bearing itself or other important parts. If the operating conditions remain unchanged, any temperature change may indicate that a failure has occurred.

WSBC bearing temperature can be measured regularly with the help of a thermometer, which can accurately measure the bearing temperature.

The importance of the bearing means that when it is damaged, it will cause the equipment to stop, so it is best to install a temperature detector for this type of bearing. Need WSBC 20220-MB, click here to learn more.

Under normal circumstances, the bearing will have a natural temperature rise immediately after lubrication or relubrication and last for one or two days.

3. Observe

If the WSBC bearing is well lubricated and can ensure the correct blocking of debris and moisture, it means that the oil seal should not be worn. However, it is best to visually inspect the bearing and periodically check the oil seal when opening the bearing housing again.

Check the condition of the oil seals near the bearing to ensure that they are sufficient to prevent hot or corrosive liquids or gases from penetrating into the bearing along the axis. The protective ring and the labyrinth oil seal should be coated with grease to ensure its large protective effect. If the oil seal is worn, it should be replaced as soon as possible.

In addition to preventing impurities from entering the WSBC bearing, the function of the oil seal is to keep the lubricant in the bearing housing. If the oil seal leaks, you should immediately check whether the oil seal has been worn or damaged or the oil plug is loose. The oil leakage phenomenon may also be caused by the loosening of the joint surface of the bearing box or the phenomenon of stirring and oil leakage caused by the excessive addition of lubricant. Check the automatic lubrication system to ensure that the oil or grease enters the bearing correctly, and ensure the correct amount of addition.

At the same time, check the lubricant for discoloration or blackening. If this phenomenon occurs, it usually indicates that the lubricant is deteriorated or contains impurities. To be replaced.

Hot Topics

Copyright © Wuxi Spark Bearings Co.,Ltd Co., Ltd All Rights Reserved. Sitemap

www.spark-bearing.com. Profession in Roller Bearings, Ball Bearings and Taper Toller Bearings-China Suppliers.