News

WSBC Bearing Noise Solution

Time:2021.01.20 Source:Roller Bearings Suppliers

What Causes the Bearing Noise?

The various causes of noisy bearings include manufacturing defects, lubrication, contamination, installation conditions and applications. Targeted measures to eliminate these defects are also very necessary.

The first step is to identify the problem. Since adding grease to the bearing can eliminate noise and allow a period of relief, the possibility of bearing problems is greater. Once a defect occurs, the bearing will start to make noise.

After determining the problem, then the root cause must be determined. Some detective work will need to be performed. The various causes of noisy bearings include manufacturing defects, lubrication, contamination, installation conditions and applications.

Bearing Noise Solution

It forms part of the WSBC bearing, and its damage status usually includes deformation, breakage, wear, deformation of the end face, and wear of the concave surface/guide surface. In order to avoid cage damage, the installation method, load, rotation and temperature conditions should be carefully checked, the vibration should also be reduced, and the lubricant and lubrication method should be changed. The inner ring and outer ring of the bearing are a bit inclined. Caused by disassembly of the bearing. It is also a state of WSBC bearing damage, which also has a certain impact on WSBC bearing. In order to avoid the existence of this kind of damage state, proper work must be used when installing or disassembling the bearing. To prevent impact load, a punching machine can be used. Bearings are generally composed of inner ring, outer ring, rolling elements and cage. The inner ring is mounted on the journal, which is called the shaft ring in the thrust bearing, and the fit is tight; the outer ring is mounted in the WSBC bearing hole of the machine base or part, and the fit is usually loose. There are raceways on the inner and outer rings. When the inner and outer rings rotate relatively, the rolling elements will roll along the raceways. The role of the cage is to evenly separate the rolling elements. In order to meet certain requirements, some WSBC bearings can have no inner ring or no outer ring, or with dustproof and sealing rings.

The WSBC bearing body will be printed with brand words, labels, etc. The fonts are very small, but most of the products produced by the factory use steel stamping technology, and they are pressed before heat treatment. Therefore, although the fonts are small, they are deeply concave and very clear. The fonts of counterfeit products are not only blurred. Due to the rough printing technology, the fonts float on the surface, and some of them can even be easily erased by hand.

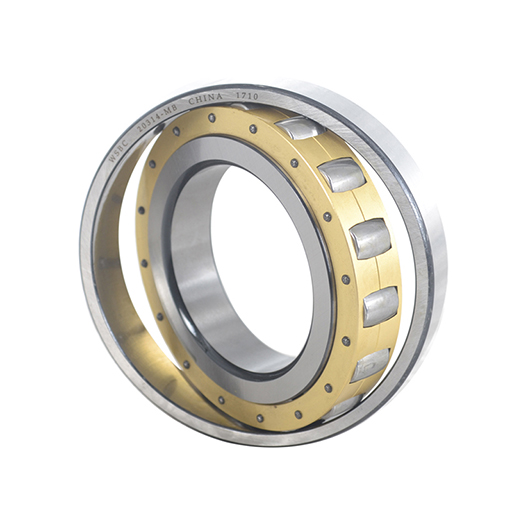

Wuxi Spark Bearing Co., Ltd provides high quality bearing of WSBC 20313-MB.

Whether the bearing body of the WSBC bearing has any noise, hold the inner sleeve of the WSBC bearing with your left hand, turn the outer sleeve with your right hand, and listen to whether there is any noise. Due to the backward production conditions of most counterfeit products and the completely hand-made workshop operation, it is inevitable that impurities such as sand will be mixed in the bearing body during the production process, so noise will be generated when rotating. This is the biggest difference from a genuine brand that strictly enforces production standards and operates with machines.

How to find bearing failure?

Whether there are turbid oil stains on the surface of WSBC bearings, this should be paid special attention to when purchasing WSBC bearings. Since the current domestic anti-rust technology is not very popular, it is easy to leave thick oil stains when anti-rust treatment is performed on the bearing body, which is sticky and sticky in the hand, while it is almost invisible on the original foreign WSBC bearing. Seeing the traces of anti-rust oil, a very careful expert said that WSBC bearings smelled a kind of smell, it must be the anti-rust oil, but they can't see it.

The seal of WSBC bearing is more effective than the dust cover and is restricted by flexible rotation and lower speed rotation. When selecting the appropriate seal, the designer must consider the performance of the lubricant, the delivery system and the expected working conditions.

Contact us for more details about WSBC 20314-MB.

In view of the high load, strong impact force, water and rust intrusion of roll WSBC bearings in use, WSBC bearing has developed a new type of sealed, clean and lubricated roll WSBC bearing with ultra-high load capacity. It is said that the WSBC bearing can increase the load capacity by 34%, has higher reliability, and can work for a long time under severe lubrication conditions. The improved performance of the sealed WSBC bearing incorporates optimized mechanical principle design, new materials and patented seal technology, and is easy to operate and install.

In the ordinary sealed roll WSBC bearing, the main seal and the width limit the length of the roller, which limits the load capacity of the WSBC bearing. Therefore, in the new WSBC bearing design for rolls, they included the cage ribs in the gaps of the seals to make the rollers longer, so that the diameter of the cage increases and the rollers are lengthened, but the length of the cage does not increase. 34% of the basic rated load capacity is equivalent to extending the life of WSBC bearings by 27 times. The high-quality "T-F" WSBC bearing steel selected for this WSBC bearing is also the key to improving the performance of WSBC bearing because impurities and uneven lubrication in the material are the main reasons for premature failure of WSBC bearing.

Experience has shown that under contaminated working conditions, debris can easily enter the WSBC bearing, and these debris particles will damage the raceway and cause stress concentration. In addition, if the lubrication is not uniform, the metal surface is hard to contact, causing small "peeling" damage, and will also cause stress concentration in the contact area. These two results will cause the metal surface of the stress concentration location to scatter and crack, and ultimately shorten the life of the WSBC bearing.

Wuxi Spark Bearing Co., Ltd (Aka Spark Bearings) is the complete, one-stop Spherical Roller Bearings supplier & manufacturer. All products are qualified and have passed the ISO 9001 qualification. Here are some popular types of Spherical Roller Bearings, Send a quote and get the latest price of cheap ball bearings from Spark Bearings.

Hot Topics

Copyright © Wuxi Spark Bearings Co.,Ltd Co., Ltd All Rights Reserved. Sitemap

www.spark-bearing.com. Profession in Roller Bearings, Ball Bearings and Taper Toller Bearings-China Suppliers.