News

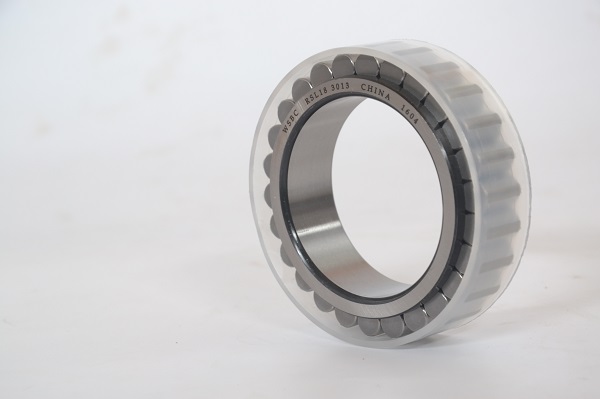

Vibration Temperature Causes Failure Analysis of Cylindrical Roller Bearing

Time:2020.06.30 Source:Roller Bearings Suppliers

In the process of using cylindrical roller bearings, it can be said that the impact of vibration and temperature on cylindrical roller bearings is very large, let us first look at the impact of bearing vibration on cylindrical roller bearings.

Vibration can be said to be quite sensitive to bearing damage, and flaking, indentation, rust, cracks, wear, etc. will be reflected in bearing vibration measurements. Therefore, the size of the vibration can be measured by using a special cylindrical roller bearing vibration measuring device (frequency analyzer, etc.), and the specific circumstances of the abnormality cannot be inferred from the frequency points. The measured value differs depending on the use condition of the bearing or the installation position of the sensor, etc. Therefore, it is necessary to analyze and compare the measured value of each machine in advance to determine the judgment standard.

We next look at the effect of temperature on bearings.

High temperature often indicates that the bearing is in an abnormal condition. High temperature is also harmful to the lubricant of cylindrical roller bearings. Sometimes overheating of the bearing can be attributed to the lubricant of the bearing. Long-term continuous rotation of the bearing at temperatures exceeding 125°C will reduce bearing life. The causes of high-temperature bearings include: insufficient lubrication or excessive lubrication, lubricants. It contains impurities, excessive load, bearing damage ring, insufficient clearance, high friction caused by oil seal, etc. Need bearing WSBC RSL18 3013,22236CC/W33 pls click here.

Therefore, it is necessary to continuously monitor the bearing temperature, whether it is to measure the cylindrical roller bearing itself or other important parts. If the operating conditions remain unchanged, any temperature change may indicate that a failure has occurred.

The periodic measurement of the bearing temperature can be aided by a thermometer, such as a digital thermometer, which can accurately measure the bearing temperature and display it in units of ℃ or Fahrenheit. The importance of the bearing means that when it is damaged, it will cause the equipment to stop, so it is best to install a temperature detector for this type of bearing.

In order to maintain the original state of the cylindrical roller bearing in good condition for as long as possible , maintenance and inspection are required to prevent accidents before they occur, to ensure the reliability of operation, and to improve productivity and economy.

Maintenance is best performed regularly in accordance with the operating standards of the machine's operating conditions. The contents include monitoring the running status, replenishing or replacing lubricants, and regular disassembly inspections.

1.Overhaul of the cylindrical roller bearings under running conditions, overhaul of the rotary sound, vibration, temperature, overhaul of lubricant properties, and determination of the timing of lubricant replenishment or replacement.

2.Overhaul of cylindrical roller bearings When performing regular overhaul and replacement of machinery, fully observe the removed bearings, confirm the condition of the track surface and whether there is damage, and confirm whether it can be reused.

The maintenance items in operation include the rotating sound of the bearing, vibration, temperature, lubricant condition, etc.

(1)Rotation sound of cylindrical roller bearing

Use a hearing aid to investigate the noise level and sound quality.

Even if a few cylindrical roller bearings produce abnormal sounds and irregular sounds in the state of fatigue peeling, it is possible to hear them if they are skilled.

(2)Vibration of cylindrical roller bearings

Use the bearing vibrator to quantitatively analyze and analyze the vibration amplitude, frequency, etc., and infer the damage status of the bearing based on this.

However, because the use conditions of the bearing are different from the measurement position, it is necessary to make use of the measurement value of the machine to determine the determination criterion.

(3)Temperature of cylindrical roller bearings

The bearing temperature usually rises slowly after the start of operation and reaches saturation after a period of time. The steady temperature of the bearing is different due to the mechanical heat capacity, heat release, speed and load.

If the bearing temperature does not reach saturation and rises abnormally, consider the reasons shown on the following page, stop the operation, and take necessary measures.

(4) Lubrication

Investigation of greases and lubricants in use is effective for understanding the running status of bearings. Of course, the leakage, discoloration, and deterioration of grease or oil can be judged from the moisture, debris, and iron powder contained therein.

When it is considered that there is leakage of lubricant and the mixing of foreign materials such as iron powder and metal powder, quantitative observation of the leakage amount, temperature and vibration of the cylindrical roller bearing is performed regularly, and if there is any abnormality, early maintenance is carried out .

Wuxi Spark Bearing Co.,Ltd is one of famous roller bearings manufacture in China , can produce different type of roller bearings in high quality .

Hot Topics

Copyright © Wuxi Spark Bearings Co.,Ltd Co., Ltd All Rights Reserved. Sitemap

www.spark-bearing.com. Profession in Roller Bearings, Ball Bearings and Taper Toller Bearings-China Suppliers.