News

The Structure And Performance Of WSBC Bearing

Time:2020.08.18 Source:Roller Bearings Suppliers

1. Thrust angular contact ball bearings in WSBC bearings

The contact angle of thrust angular contact ball bearings is generally 60°. Commonly used thrust angular contact ball bearings are generally two-way thrust angular contact ball bearings, which are mainly used for precision machine tool spindles. They are generally used in conjunction with double row cylindrical roller bearings and can withstand two-way shafts. It has the advantages of high precision, good rigidity, low temperature rise, high speed, and convenient assembly and disassembly.

2, deep groove ball bearings in WSBC bearings

Structurally, each ring of a deep groove ball bearing has a continuous groove raceway with a cross section approximately one third of the equatorial circumference of the ball. Deep groove ball bearings are mainly used to bear radial load, but also can bear certain axial load. When the radial clearance of the bearing increases, it has the properties of an angular contact ball bearing and can withstand alternating axial loads in two directions. Compared with other types of bearings of the same size, this type of bearing has a small friction coefficient, high limit speed, and high accuracy. It is the preferred bearing type for users when selecting models. Deep groove ball bearings are simple in structure and easy to use. They are the largest type of WSBC bearing with the largest production batch and the widest application range.

3. Thrust tapered roller bearings in WSBC bearings

Since the rolling elements in thrust tapered roller bearings are tapered rollers, the rolling generatrix and the raceway generatrix of the washer are structurally converged at a certain point on the shaft center line of the bearing, so the rolling surface can form pure rolling and high limit speed. For thrust cylindrical roller bearings. Features: Thrust tapered roller bearings can withstand unidirectional axial load. The type code of thrust tapered roller bearing is 90000 type.

4. The structure and performance characteristics of double-row tapered roller bearings in WSBC bearings

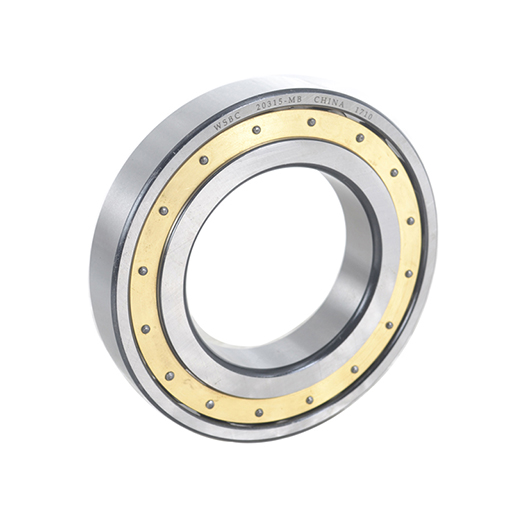

Double-row tapered roller bearings have various structures. The largest is the 35000 type. It has a double raceway outer ring and two inner rings. There is a spacer between the two inner rings. The clearance can be adjusted by changing the thickness of the spacer. This type of bearing can bear bidirectional axial load while bearing radial load, and can limit the axial displacement of the shaft and housing within the axial clearance of the bearing. Structural features of tapered roller bearings. The type code of the tapered roller bearing is 30000, and the tapered roller bearing is a separable bearing. Tapered roller bearings are mainly used to bear combined radial and axial loads, mainly radial loads. Compared with angular contact ball bearings, the bearing capacity is large and the limit speed is low. Tapered roller bearings can withstand axial load in one direction and can limit axial displacement of the shaft or housing in one direction.WSBC Bearing 20315-MB online, contact us freely for more details.

There are many reasons for the failure of WSBC bearings. All influencing factors in the design and manufacturing process will be related to the failure of WSBC bearings, which is not easy to determine by analysis. In general, it can be considered and analyzed from two aspects: use factors and internal factors.

The use factor mainly refers to whether the installation adjustment, use and maintenance, maintenance and repair meet the technical requirements. The installation prerequisite is one of the primary factors in the use factors. WSBC bearings often change the stress state between the components of the complete set of WSBC bearings due to differences in installation. WSBC bearings operate under abnormal conditions and fail early. According to the technical requirements of WSBC bearing installation, use, maintenance and maintenance, monitor and inspect the load, speed, working temperature, vibration, noise and lubrication conditions of the WSBC bearing in operation, and find the cause immediately and make adjustments when the abnormality is found. Bring it back to normal. In addition, it is also very important to analyze and repair the quality of the grease and the nearby medium and atmosphere.

Intrinsic factors mainly refer to the three major factors that determine the quality of WSBC bearings, such as structural design, manufacturing technology and material quality.

First of all, the WSBC bearing life will be longer only if the structural design is fair and has improved predecessor. The manufacture of WSBC bearings generally involves multiple processing steps such as casting, heat treatment, turning, grinding and assembly. The fairness of the processing technology, the improvement of the predecessor and the stability will also affect the life of the WSBC bearing. Among them, the heat treatment and grinding process that affect the quality of finished WSBC bearings are often more directly related to the failure of WSBC bearings. In recent years, studies on the deteriorating layer of the working surface of WSBC bearings show that the grinding process is closely related to the surface quality of WSBC bearings.

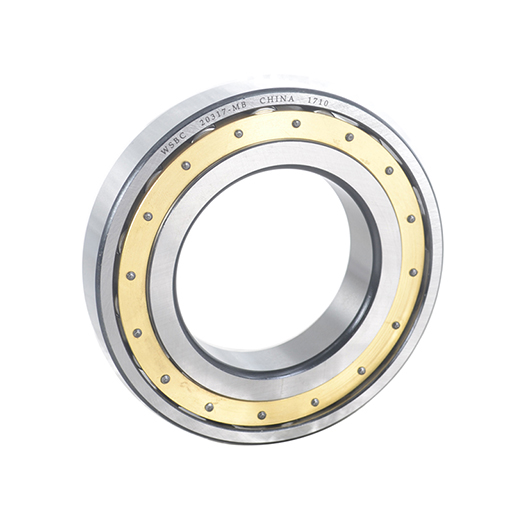

The metallurgical quality of WSBC bearing materials used to be the main factor affecting the early failure of dynamic WSBC bearings. With the improvement of metallurgical technology (such as vacuum degassing of WSBC bearing steel, etc.), the quality of raw materials has been improved. The proportion of raw material quality factors in the failure analysis of WSBC bearings has dropped significantly, but it is still one of the main factors affecting the failure of WSBC bearings. The selection of materials is still a factor that must be considered in the failure analysis of WSBC bearings.Wuxi Spark Bearing Co.,Ltd provides WSBC 20317-MB, click here to buy it.

The main task of WSBC bearing failure analysis is to find out the main factors causing WSBC bearing failure based on a large number of background materials, analysis data and failure modes, so as to propose improvement measures to extend the service life of WSBC bearings and avoid WSBC bearings Sudden early failure occurs.

Wuxi Spark Bearing Co.,Ltd provides high-quality bearings with competitive price. Our customers are in more than 50 countries and regions all over the world. They all trust our products very much. A large number of bearings are purchased every month.

Hot Topics

Copyright © Wuxi Spark Bearings Co.,Ltd Co., Ltd All Rights Reserved. Sitemap

www.spark-bearing.com. Profession in Roller Bearings, Ball Bearings and Taper Toller Bearings-China Suppliers.