News

Six Common Situations of Bearing Damage

Time:2019.12.16 Source:Roller Bearings Suppliers

During the use of the bearings, it will cause failures due to various reasons, so that the equipment cannot be used frequently. So what are the causes of bearing problems? Here is a list of six common situations of failures encountered in the process of recycling bearings.

1. Glue failure

Glue failure usually occurs because of cementation, so what is cementation? How does cementation happen? Cementing refers to the phenomenon that local metal on the surface adheres to another metal surface. Cementing occurs because the bearing is continuously used at high speed and overload in the case of inadequate lubrication. With resistance and heating of the bearing, the temperature of the bearing will rise rapidly within a short time, causing the surface of the bearing to burn and adhere.

2. Bearing cracking.

Bearing cracking leads to mechanical failure. Bearing cracking is a common cause of bearing failure. Bearing cracking is mostly caused by excessive load. Besides, improper installation, like grinding, heat treatment, improper placement, and excessive temperature, etc. will also lead to the cracking failure of the bearings. Also, installation specifications and installation sequences are some of the reasons that can cause bearing cracking.

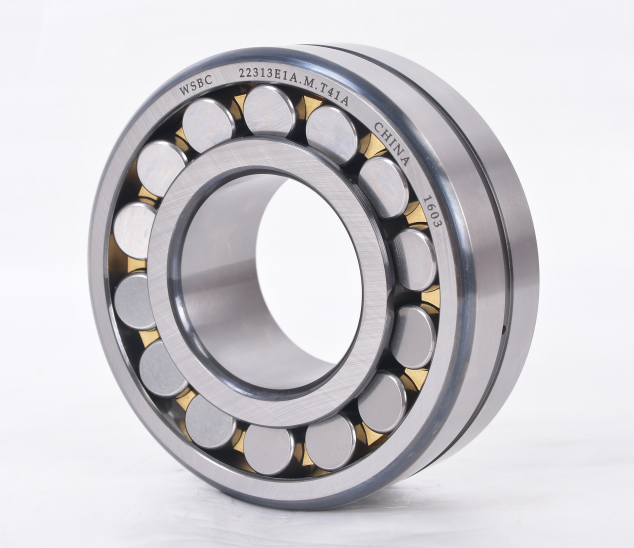

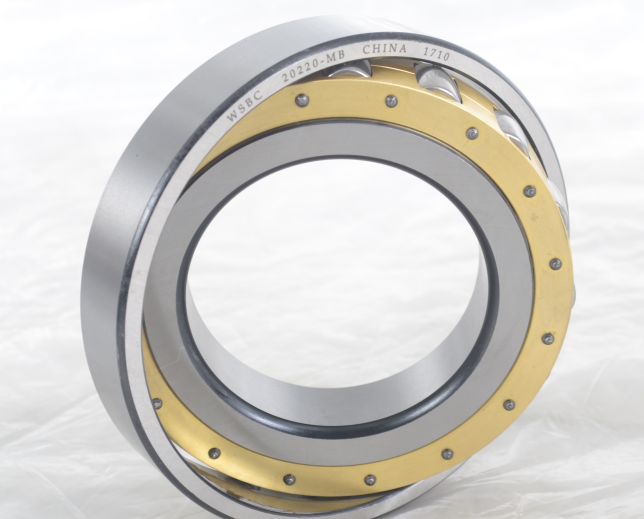

3. Damage of the bearing cage.

Most of the damage of bearing cage is caused by improper installation and use. Improper use and installation will deform the bearing cage. Deformation of the bearing cage will increase the resistance between it and the rollers, which will cause some of the rollers to become stuck and cannot be rotating. It will also cause interference between the cage and internal bearings. If it is not handled in time, the bearing will be damaged.

4. Plastic deformation

The leading cause of plastic deformation is the bearing has suffered an excessive impact load or static load, it may also be the additional load caused by thermal deformation, or it may be an indentation or a scratch on the raceway surface caused by an invaded high hardness object. The occurrence of this situation will cause the bearing to emit violent vibration and noise during the rotating process. If an indentation occurs, the surface parts will possibly fall off.

5. Corrosion of the bearing

Bearing corrosion is one of the severe problems that bearings face. The cause of bearing corrosion is caused by the indirect invasion of water, acid, and alkali. This corrosion is fatal to high-precision bearings and will cause the bearings to malfunction. This happens because after the bearing stops working, the temperature on the bearing surface will drop below the dew point, and water molecules will condense into water on the bearing surface and cause the bearing to be corroded. Another type of corrosion is electrical corrosion. The occurrence of electrical corrosion is a reaction between the current and oil film on the surface of the bearing. The oil film will spark and cause the bearing to be electrically corroded.

6. Bearing wear

The wear of the bearing is mainly caused by the invasion of dust and impurities. The absolute movement of the raceway and the roller body will cause the surface to wear. Besides, inadequate lubrication will also increase wear. This abrasion effect will increase the gap of the bearing, make the bearing surface rougher, resulting in a reduction in the accuracy of the bearing. The decline in the accuracy of the bearing will reduce the efficiency of the machine, and it will make the machine's oscillation sound and noise even greater.

Hot Topics

Copyright © Wuxi Spark Bearings Co.,Ltd Co., Ltd All Rights Reserved. Sitemap

www.spark-bearing.com. Profession in Roller Bearings, Ball Bearings and Taper Toller Bearings-China Suppliers.