News

Selection of Spherical Roller Bearing Grease

Time:2020.08.03 Source:Roller Bearings Suppliers

1. The principle of selection of spherical roller bearing grease

When choosing lubricating grease, it is mainly based on the working environment, working temperature and load condition of the spherical roller bearing.

(1) Working environment

Mainly refers to the minimum and maximum temperature of the working environment, air humidity, whether it contains corrosive gas or excessive dust, etc. For example, when used outdoors in severe cold areas, lithium-based low-temperature grease should be used; calcium-based grease should be used in places with high humidity and high water; in dry and low-water situations, sodium soluble in water is suitable Base grease.

(2) Working temperature

One is the lowest temperature of the operating environment, and the other is the highest temperature that may occur during operation. When the working temperature is high, a high temperature grease with a higher dropping point should be selected. The actual maximum operating temperature should be 10-20C lower than the dripping point of the grease (synthetic grease should be 20-30C).

2. How to inject grease for spherical roller bearings

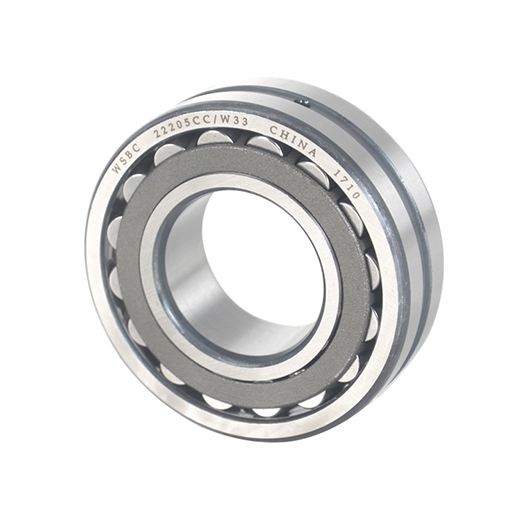

There are two types of grease injection tools for spherical roller bearings, manual grease injection and pressure grease injection, commonly known as oil guns; larger production, use and repair units may use special grease injection machines with metering devices (tanks or barrel). WSBC 22205 CC/W33 bearings online , if you interested , pls click here to learn more :

Note: In the absence of the above special equipment, clean bamboo boards or copper boards without burrs can be used. The use of steel tools with edges and corners should be prohibited.

3. Grease injection amount of bearing grease

(1) The effect of grease injection on the use of spherical roller bearings

For sealed bearings, they have been filled with appropriate grease during production; for open bearings, although a sealing device is provided to prevent grease leakage, it will still be gradually reduced due to a small amount of leakage during use. Constantly add.

Practice has proved that the amount of grease injected into the spherical roller bearing will have a certain impact on its operation. Too little grease injection will easily cause insufficient lubrication. In severe cases, it will cause dry friction, generate higher heat, and cause the bearing to be scrapped in a short time due to wear, which may have a serious impact on the entire equipment. Too much grease injection will result in greater rolling resistance of the rolling elements of the bearing. The temperature of the grease in the bearing will be higher. When it reaches its dropping point, it will turn into liquid and be lost. In the end, the serious consequences of too little grease injection will occur. Leaking grease causes waste and pollutes the environment.

(2) The principle of grease injection

The principle of grease injection: as long as the bearing can be fully lubricated, the less the better.

Based on practical experience, the following principles are more appropriate.

For open bearings, the appropriate amount of grease injection should be based on the volume and size of the bearing chamber and the speed of the spherical roller bearing used (for AC motors, the number of poles can also be used instead of speed) to simply calculate the amount of grease.

For the bearing chamber structure with an oil baffle plate (also called an oil slinger), the amount of grease for the first injection should be increased appropriately, and no grease should be injected into the cavity of the bearing cover (here is to accept the "waste grease "The trash can", the grease in it will not enter the bearing for lubrication, so the newly injected grease will be wasted). With this structure, because the grease in the bearing chamber will become less and less, if the grease is not added regularly as required, the lubrication effect will be reduced due to too little grease, and the grease will eventually become dry due to overheating, making the entire spherical roller The bearing is damaged. WSBC 22206 CC/W33 bearings online , if you interested , pls click here to learn more :

(3) Matters needing attention

When filling grease, the site should be clean and clean, and the tools used should be cleaned with gasoline. After the grease has been injected, other parts should be assembled as soon as possible to prevent the grease entering the bearing from entraining dust and debris, especially sand and iron filings.

(4) Grease injection of rolling bearings during operation

For machinery that uses open bearings, after running for a certain period of time, grease should be added to the bearing chamber. For those with oil injection system, it can be carried out without disassembling the machine, otherwise the bearing cover should be disassembled to directly fill the bearing chamber with oil. Attention should be paid to using the same grade of grease as the original grease to avoid harmful reactions of different components of grease to reduce or even lose lubrication, causing overheating and damage to the spherical roller bearing.

Note: If the original grease has deteriorated, it should be thoroughly removed with a solvent such as gasoline, and then refilled with new grease.

(5) Time interval for replenishing grease during operation

The expected life of grease is affected by many factors. For example, the type of grease, the speed and temperature of the bearing, the amount of dust and corrosive gas in the working environment, the design of the sealing device and the actual effect of the situation.

For sealed or smaller bearings, both the spherical roller bearing itself and the grease in it determine the life of a set of bearings. It is not necessary and impossible to add or replace grease in the middle.

According to experience, the effect of temperature on the time interval for replenishing grease is: when the temperature (the temperature measured on the outer ring of the bearing) reaches above 40C, every 15C increase will shorten the time interval for replenishing grease by half.

Hot Topics

Copyright © Wuxi Spark Bearings Co.,Ltd Co., Ltd All Rights Reserved. Sitemap

www.spark-bearing.com. Profession in Roller Bearings, Ball Bearings and Taper Toller Bearings-China Suppliers.