News

Selection And Function Of WSBC Bearings

Time:2020.08.12 Source:Roller Bearings Suppliers

一. Selection of WSBC bearings

1. Selection of WSBC bearing model: WSBC bearing model is generally selected by the user's technical personnel according to the use conditions and load bearing of the supporting product. The business personnel mainly understand whether the actual load of the user is consistent with the selected WSBC bearing. If the WSBC bearing does not meet the requirements for use, the customer should be advised to change the model as soon as possible, but unless there is no problem in selecting the model for a special product.

2. The choice of WSBC bearing clearance: When purchasing WSBC bearings, users generally only inform the type and grade of WSBC bearings. They rarely ask for the clearance of WSBC bearings. Business personnel must ask about the use conditions of WSBC bearings and WSBC The bearing speed, temperature and fit tolerance are directly related to the choice of WSBC bearing clearance. Generally, motors with speeds below 3,500 rpm mostly use CM clearance. For example, high-temperature and high-speed motors require relatively large clearances. After assembly, the clearance of WSBC bearing will be reduced due to the expansion of the inner hole and the shrinking of the outer circle. The reduction of the clearance = interference × 60% (except the WSBC bearing housing is aluminum). For example, the clearance before assembly of WSBC bearing is 0.01mm, and the interference during assembly is 0.01mm, then the clearance after assembly of WSBC bearing is 0.004mm. In theory, the noise and life of the WSBC bearing reach the best state when there is zero clearance. However, considering the temperature rise in actual operation, the clearance of the WSBC bearing after assembly is 0.002mm-0.004mm.

3. Grease selection: The selection of grease is generally based on the speed, temperature resistance, noise requirements and starting torque of the WSBC bearing. The business personnel are required to have a good understanding of the performance of various greases.

4. Selection of WSBC bearing seal type: The lubrication of WSBC bearing can be divided into oil lubrication and grease lubrication. Oil-lubricated WSBC bearings are generally selected in the form of WSBC bearings, and grease-lubricated WSBC bearings are generally sealed with dust caps or rubber seals. The dust cover is suitable for high temperature or good use environment. The seals are divided into contact seal and non-contact seal. Contact seal has good dustproof performance but large starting torque, and non-connected seal has small starting torque but sealing performance No contact is good.

WSBC bearings are currently professionally manufactured in industries such as WSBC bearings for automotive motors, WSBC bearings for home appliances, WSBC bearings for motorcycles, and WSBC bearings for health care motors, so that the noise and life of WSBC bearings reach the best condition.

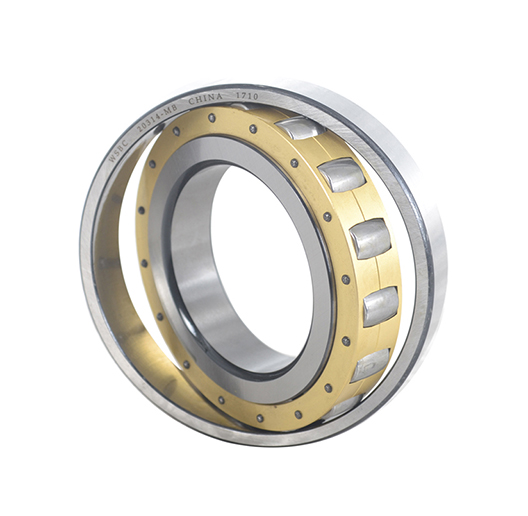

Need WSBC Bearing 20313-MB, pls kindly click here to buy it.

二. Matters needing attention when using WSBC bearings

1. Tolerance selection and control of shaft and WSBC bearing chamber: After WSBC bearing is pressed into WSBC bearing, it should rotate flexibly without blocking. If the rotation is obviously not flexible, it indicates that the size of the shaft is too large and the tolerance needs to be lowered. If the WSBC bearing is pressed into the shaft and turned by hand, there is an obvious "sand" feeling, it may be because the tolerance of the shaft is too large or the roundness of the shaft is not good. Therefore, when controlling the tolerance of the shaft and the WSBC bearing chamber, the roundness must be controlled. At present, many domestic manufacturers only control the tolerance, but not the roundness.

2. The assembly method of WSBC bearings: Because WSBC bearings are high-precision products, improper assembly can easily cause damage to the WSBC bearing raceway and cause damage to the WSBC bearing. WSBC bearings should have special molds when assembling them, and they cannot be knocked at will. When pressing into the shaft, only small circles can be forced, and large circles can only be forced. When assembling, it is required to use air pressure or hydraulic pressure. The upper and lower molds should be outside the horizontal state during press-fitting. If there is a tilt, the WSBC bearing channel will be damaged due to force, which will cause the WSBC bearing to produce noise.

3. Prevention of assembly foreign matter: When WSBC bearing is installed on the rotor for dynamic balancing, it is easy to enter the iron filings generated during dynamic balancing into the WSBC bearing. Therefore, it is best to perform dynamic balancing before installing the WSBC bearing. For the convenience of assembly, some manufacturers apply some oil or grease in the WSBC bearing chamber for lubrication effect during assembly, but it is often difficult for operators to control the amount. If the oil or grease accumulates in the WSBC bearing chamber a lot, the WSBC bearing It is easy to enter the WSBC bearing along the shaft when rotating. It is best not to apply oil or grease to the WSBC bearing room. If it is not possible to apply it, it must be controlled not to accumulate in the WSBC bearing room.

4. Prevention of lacquer rust: The characteristic of lacquer rust is that it mostly occurs in sealed motors. The sound of the motor is very good during assembly, but after some time in the warehouse, the abnormal noise of the motor becomes very large. Remove the WSBC bearing There is severe rust. In the past, many manufacturers thought it was the problem of WSBC bearings. After our continuous publicity, now the motor factory has realized that the problem is mainly the insulating paint. This problem is mainly because the acidic substance volatilized from the insulating paint forms corrosive substances under a certain temperature and humidity, which causes the WSBC bearing to be damaged after corroding the WSBC bearing channel. At present, the problem can only be to choose a good insulating paint, and ventilate for a period of time after drying and assembly.

Wuxi Spark Bearing Co.,Ltd provides high quality Bearing 20314-MB, contact us to learn more about it.

The life of WSBC bearings is closely related to manufacturing, assembly, and use. Every link must be done well in order to make the WSBC bearings in the best operating state, thereby extending the service life of the WSBC bearings.

Wuxi Spark Bearing Co.,Ltd provides high quality and competitive price bearings. Our products export to more than 30 countries and regions around the world, and have established long-term cooperative relations with our customers. Customers are very satisfied with our products. In the future, we also hope that more customers can cooperate and develop with us.

Hot Topics

Copyright © Wuxi Spark Bearings Co.,Ltd Co., Ltd All Rights Reserved. Sitemap

www.spark-bearing.com. Profession in Roller Bearings, Ball Bearings and Taper Toller Bearings-China Suppliers.