News

Replacement Steps of Separation Bearing of Cement Mixer

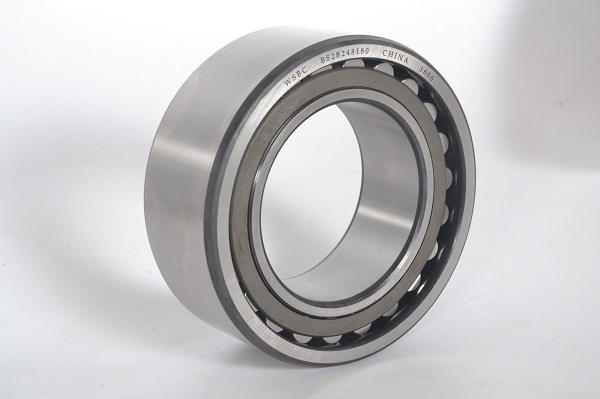

Time:2020.06.19 Source:Roller Bearings Suppliers

The steps to replace the separation bearing of the cement mixer are as follows:

1. Remove the split fork guard (A) from the clutch housing (B)

2. With the aid of a vise, squeeze the spring (D) of the separation fork device, remove the separation fork (C) from the clutch housing (B), and remove the separation bearing (E).

3. Rotate the separation bearing by hand to check the bearing clearance. If the clearance is too large, replace the new separation bearing.

Note: The separation bearing is filled with grease, do not use solvent to clean it.

4. Coat the separation fork (A), separation fork bolt (B), separation bearing (C) and separation bearing guide post (D) with urea grease.

5. When the separation fork between the pawls of the sliding separation bearing is inserted along the circular hole on the clutch housing, install the separation bearing on the main shaft.

6. Align the separation fork pawl with the separation fork bolt, and then press the separation fork evenly onto the separation fork bolt.

7. Install the mixer fork separation shield (E). Confirm that the guard is fastened to the release fork and clutch housing.

8. Slide the separation fork (A) left and right to ensure correct installation on the separation bearing (B), and the separation bearing can slide smoothly.

Causes and treatment methods of bearing noise of cement mixer truck

Vibration is commensurately sensitive to the damage of cement mixer truck bearings. Peeling, indentation, rust, cracks, wear, etc. will be reflected in the vibration measurement of the cement mixer truck bearings. Therefore, the size of the vibration can be measured by using a special bearing vibration measuring device, and the specific situation of the abnormality can be inferred by the frequency distribution. The measured value is different according to the use premise of the cement mixer truck bearing or the installation position of the sensor, so it is necessary to analyze and compare the measurement value of each machine in advance to determine the judgment scale. Wuxi Spark Bearing Ltd have enough stock for WSBC 801215A 23136CCK/W33 bearings , pls click here.

The influence of temperature on the bearing of the cement mixer truck, the high temperature often indicates that the bearing is in an abnormal condition. High temperature is also harmful to the lubricant of cement mixer truck bearings. Sometimes the bearing overheating can be attributed to the bearing lubricant. Long-term continuous rotation of bearings at temperatures exceeding 125°C will reduce bearing life. The factors that cause high-temperature bearings are: insufficient lubrication or excessive lubrication, impurities contained in the lubricant, excessive load, wear on the bearings of the cement mixer truck, insufficient clearance, and high friction caused by the oil seal, etc.

Therefore, it is necessary to continuously monitor the bearing temperature of the cement mixer truck, whether it is to measure the bearing itself or other important parts. If the operating conditions remain unchanged, any temperature change may indicate that a failure has occurred.

Rolling sound of bearing of WSBC cement mixer and its control method

The raceway sound is a kind of smooth and continuous sound produced by the moving elastic body moving on the raceway surface when the bearing is running. It is a unique basic sound that will occur in all moving elastic bearings. The general bearing sound is equal to the raceway sound plus other sounds. The raceway sound of the ball bearing is irregular, the frequency is above 1000Hz, its main frequency does not change with the speed, but its total sound pressure level increases with the speed. For a bearing with a loud raceway sound, the sound pressure level of the raceway sound decreases with increasing viscosity; while for a bearing with a small raceway sound, the sound pressure level changes from decreasing when the viscosity increases to about 20 mm2/s or more To increase.

The greater the rigidity of the bearing housing, the lower the total sound pressure level of the raceway sound. If the radial clearance is too small, the total sound pressure level and main frequency of the raceway sound will increase sharply as the radial clearance decreases. The methods to control the raceway sound are: select low-noise bearings, that is, bearings with very low waviness, and carefully choose the premise of use. The sound of the raceway often affects the noise of the entire machine. Reducing the sound of the raceway can reduce the noise of the whole machine.

Why the bearings of cement mixer truck can run stably under the condition of high speed and high pressure

Prevention of bearing paint rust on cement mixer trucks: paint rust is characterized by frequent occurrence of sealed motors. The motor sounds very well during assembly, but after being placed in the warehouse for some time, the abnormal noise of the motor becomes very large and removed. Thrust roller bearings are severely rusted. Many manufacturers used to think it was a problem with thrust roller bearings. After our continuous promotion, motor manufacturers have realized that the problem is mainly insulating paint. This problem is mainly because the acidic substance volatilized from the insulating paint forms a corrosive substance under a certain temperature and humidity, which causes the thrust roller bearing to be damaged after corroding the thrust roller bearing channel. At present, the problem can only be to choose good insulating paint and assemble it after drying for a period of time.

Steel requirements

The rigidity of general roller bearings is large, and the rigidity of ball bearings is small. Angular contact ball bearings and tapered roller bearings use a preload method to increase the support height.

Friction torque

For machines (such as instruments) that require low friction torque, ball bearings should be used as much as possible, and contact sealed bearings should also be avoided.

Installation and disassembly

When loading and unloading frequently, separate bearings can be used, or self-aligning quill bearings and self-aligning quill bearings with tapered sleeves or inner sleeves with tapered sleeves.

Axial swimming

The bearing configuration is usually fixed at one end and swimming at one end to adapt to the thermal expansion and contraction of the shaft to ensure the movement of the bearing. One is to choose the inner ring or outer ring without rib bearings, and the other is to use the inner ring and the outer ring. A clearance fit is used between the shaft or outer ring and the bearing hole.

Whether it is a four-row tapered roller bearing or a double-row cylindrical roller bearing, the basic structure is similar to the traditional rolling mill bearing, but the design of each part fully considers the problems of lubrication and heat dissipation, that is, the inner ring, outer ring, and Rings (for four-row tapered roller bearings), cages, and rollers (for double-row cylindrical roller bearings) have many slots and holes. In this way, the lubricating and heat dissipation channels formed by the grooves and holes and the bearing seats and the channels on the rolls form a reliable lubrication and heat dissipation system. Coupled with a good sealing device, the bearings can run stably under high-speed and high-pressure conditions.

Hot Topics

Copyright © Wuxi Spark Bearings Co.,Ltd Co., Ltd All Rights Reserved. Sitemap

www.spark-bearing.com. Profession in Roller Bearings, Ball Bearings and Taper Toller Bearings-China Suppliers.