News

Reasons Affecting the Friction of Cylindrical Roller Bearings

Time:2020.07.13 Source:Roller Bearings Suppliers

1. Surface properties

Due to the effects of pollution, chemical heat treatment, electroplating and lubricants, a very thin surface film (such as oxide film, sulfide film, phosphating film, chloride film, sulfide film, cadmium film, aluminum film, etc.) is formed on the metal surface ), so that the surface layer has different properties from the substrate. If the surface film is within a certain thickness, the actual contact area is still sprinkled on the base material instead of the surface film. At the same time, the shear strength of the surface film is lower than that of the base material; on the other hand, it is not easy to occur due to the presence of the surface film Sticky, so the friction force and friction factor can be reduced accordingly.

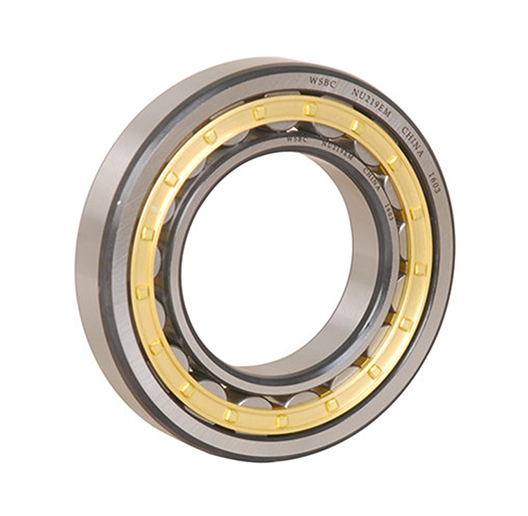

The thickness of the surface film also has a great influence on the friction factor. If the surface film is too thin, the film is easily crushed and direct contact with the matrix material occurs; if the surface film is too thick, on the one hand, the actual contact area is increased due to the softer film, on the other hand, the micro peaks on the two dual surfaces are The furrow effect on the surface film is also more prominent. It can be seen that the surface film has an optimal thickness worth seeking. Today , share WSBC NU 219 EM bearing photos as below :

2. Material properties

The friction factor of the metal friction pair varies with the nature of the mating material. Generally speaking, the friction pair of the same metal or metal with high mutual solubility is easy to stick, and the friction factor is large; otherwise, the friction factor is small. Materials with different structures have different friction characteristics. For example, graphite has a stable layered structure and the bonding force between the layers is small, so it is easy to slide, so the friction factor is small; for example, the friction pair of diamond pairs is difficult to stick due to the high hardness and the actual contact area, and the friction factor is also Smaller.

3. Temperature

The influence of the temperature of the surrounding medium on the friction factor is mainly caused by the change in the properties of the surface material. Bowden et al.’s experiments show that the friction factor of many metals (such as molybdenum, tungsten, chin, etc.) and their compounds in the surrounding medium The minimum value occurs when the temperature is 700~800℃. This phenomenon occurs because the initial temperature rise reduces the shear strength, and further temperature rise causes the yield point to drop sharply, which causes the actual contact area to increase a lot. However, when a polymer friction pair or pressure is processed, the friction factor will appear to be extremely large as the temperature changes.

It can be seen from the above that the influence of temperature on the friction factor is variable. The relationship between temperature and friction factor becomes very complicated due to the influence of specific working conditions, material characteristics, oxide film changes and other factors.

4. Relative motion speed

Under normal circumstances, the sliding speed will cause the surface layer to generate heat and temperature rise, thereby changing the properties of the surface layer, so the friction factor will change accordingly.

When the relative sliding speed of the dual surface of the friction pair exceeds 50 m/s, a large amount of frictional heat is generated on the contact surface. Due to the short continuous contact time of the contact point, a large amount of frictional heat generated in an instant is too late to diffuse into the substrate, so the frictional heat is concentrated on the surface layer, so that the surface layer temperature is higher and a molten layer appears, the molten metal liquid plays a lubricating role, making the friction The factor decreases with increasing speed. For example, when the sliding speed of copper is 135m/s, the friction factor is 0.055; while at 350m/s, it decreases to 0.035. However, the friction factor of some materials (such as graphite) is hardly affected by the sliding speed. The reason is that the mechanical properties of these materials can be maintained in a wide temperature range.Today , share WSBC SL183020 bearing photos as below

:

For boundary friction, in the low speed range where the speed is less than 0.0035m/s, that is, the transition from static friction to dynamic friction, as the speed increases, the friction factor of the adsorption film gradually decreases and tends to a fixed value, and the friction factor of the reaction film It also gradually increases and tends to be fixed.

5. Load

In general, the friction factor of a metal friction pair decreases with increasing load and then tends to be stable. This phenomenon can be explained by adhesion theory. When the load is very small, the two pairs of surfaces are in elastic contact. At this time, the actual contact area is proportional to the 2/3 power of the load, and according to the adhesion theory, the friction force is proportional to the actual contact area, so the friction factor is 1 /3 power is inversely proportional; when the load is large, the two pairs of surfaces are in elastoplastic contact, and the actual contact area is proportional to the load 2/3 to 1 power, so the friction factor decreases slowly as the load increases It tends to be stable; when the load is so large that the surfaces of the two pairs are in plastic contact, the friction factor is basically independent of the load.

The magnitude of the static friction factor is also related to the duration of the static contact between the two dual surfaces under load. In general, the longer the static contact duration, the greater the static friction factor. This is due to the plastic deformation of the contact area due to the load. With the extension of the static contact time, the actual contact area will increase, and the micro peaks will be embedded into each other. Caused more deeply.

6. Surface roughness

In the case of plastic contact, since the surface roughness has little effect on the actual contact area, it can be considered that the friction factor is hardly affected by the surface roughness. For dry friction pairs with elastic or elastoplastic contact, when the surface roughness value is small, the mechanical effect is small, and the molecular force is large; vice versa. It can be seen that the friction factor changes with the surface roughness will have a minimum value.

The influence of the above factors on the friction factor is not isolated, but interrelated and influential.

Hot Topics

Copyright © Wuxi Spark Bearings Co.,Ltd Co., Ltd All Rights Reserved. Sitemap

www.spark-bearing.com. Profession in Roller Bearings, Ball Bearings and Taper Toller Bearings-China Suppliers.