News

Four reasons for the failure of sealed spherical roller bearings

Time:2020.03.20 Source:Roller Bearings Suppliers

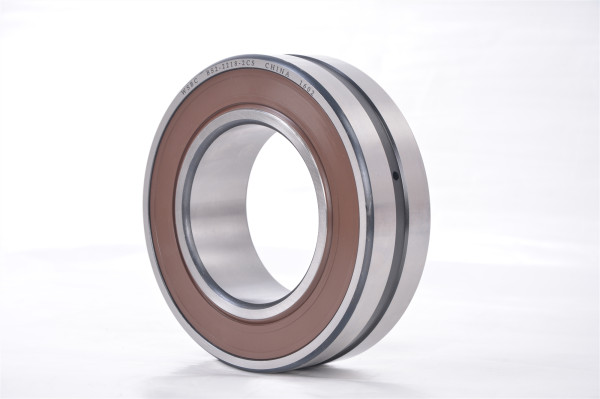

The seals of sealed spherical roller bearings can be

divided into two types: self-contained seals and external seals. The so-called

bearing comes with a seal is to make the bearing itself into a device with

sealing performance. Such as bearings with dust caps, seals and so on. This seal

occupies a small space, is easy to install and remove, and has a relatively low

cost. Wuxi Spark Bearing Co., Ltd is a modern high-tech professional

high-quality roller bearing manufacturer specializing in R & D,

manufacturing, sales and service. Our professional engineering and sales team is

willing to take care of each customer's requirements and provide cost-effective

solutions. We have summarized four reasons for the failure of sealed spherical

roller bearings, and hope to help you.

1.Sealed spherical roller bearings fail due to contact fatigue

Contact fatigue failure refers to the failure of the bearing working surface under the effect of alternating stress. Contact fatigue spalling occurs on the bearing working surface, which is often accompanied by fatigue cracks. It first occurs from the maximum alternating shear stress below the contact surface and then extends to the surface to form different spalling shapes, such as pitting or pitting. Exfoliation into small pieces is called shallow exfoliation. Due to the gradual expansion of the exfoliation surface, it often expands to the deep layer, forming a deep exfoliation. Deep spalling is the fatigue source of contact fatigue failure.

2.Sealed spherical roller bearings fail due to wear

Wear failure refers to the failure caused by the continuous wear of the metal on the working surface caused by the relative sliding friction between the surfaces. Continued wear will cause gradual damage to bearing parts, and eventually lead to loss of bearing dimensional accuracy and other related problems. The wear of Senson bearings may affect the shape change, the increase of the fit clearance and the change of the working surface morphology, which may affect the lubricant of Senson bearings or cause its pollution to a certain extent, causing the complete loss of lubrication function, and thus the loss of bearing rotation accuracy. It can't even work normally. Wear failure is one of the common failure modes of various types of bearings. According to the form of wear, it can be divided into the most common abrasive wear and adhesive wear.

Abrasive wear refers to the wear caused by the intrusion of foreign hard particles or hard foreign objects or abrasive debris on the surface of the bearing between the working surfaces of the bearing and the relative movement of the contact surface. Often, a furrow-like abrasion is caused on the bearing working surface. Hard particles or foreign objects may come from the host or from other adjacent parts of the host system and are fed into the bearing by the lubricant. Adhesive wear refers to uneven friction on the friction surface due to micro-protrusions or foreign bodies on the friction surface. When the lubrication conditions are severely deteriorated, local friction generates heat due to local friction, which can easily cause local deformation of the friction surface and friction micro-welding. When the surface metal is partially melted, the force on the contact surface will tear the local friction welding point from the substrate and increase plastic deformation.

3.Sealed spherical roller bearings fail due to fracture

The main cause of bearing fracture failure is the two major factors of defect and overload. When the applied load exceeds the strength limit of the material and causes the part to fracture, it is called overload fracture. The main reason for overload is sudden host failure or improper installation. Defects such as micro-cracks, shrinkage holes, air bubbles, large foreign objects, overheated tissues, and local burns of bearing parts can also cause fractures at the defects during shock overload or severe vibration. It should be pointed out that during the bearing manufacturing process, the raw materials can be re-inspected in the factory, the quality control of forging and heat treatment, and the control of the processing process can be correctly analyzed by the instrument to determine whether the above defects exist. In the future, control must be strengthened. But in general, the most common bearing fracture failures are overload failures.

4.Sealed spherical roller bearings fail due to changes in clearance

During the operation of the bearing, due to the influence of external or internal factors, the original fit clearance is changed, the accuracy is reduced, and the clearance change is called failure. External factors such as excessive interference, inadequate installation, expansion due to temperature rise, instantaneous overload, etc. Internal factors such as residual austenite and residual stress are in an unstable state are the main reasons for the failure of clearance changes.

Hot Topics

Copyright © Wuxi Spark Bearings Co.,Ltd Co., Ltd All Rights Reserved. Sitemap

www.spark-bearing.com. Profession in Roller Bearings, Ball Bearings and Taper Toller Bearings-China Suppliers.