News

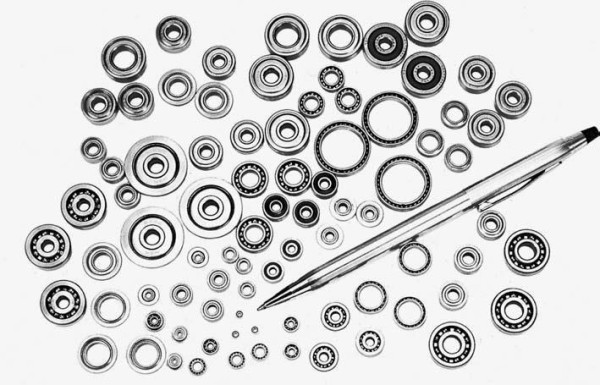

Do you know the size of the smallest bearing in the world?

Time:2020.03.04 Source:Roller Bearings Suppliers

Bearing is an important component in contemporary machinery and equipment.

Its primary function is to support the mechanical rotating body, reduce the

friction coefficient during its movement, and ensure its turning accuracy.

According to the size of the bearing, it can be divided into:

Miniature bearings, bearings with a nominal outside diameter range of less than 26mm;

Small bearings, bearings with a nominal outer diameter range of 28-55mm;

Small and medium-sized bearings, bearings with a nominal outer diameter range of 60-115mm;

Medium and large bearings, bearings with a nominal outer diameter range of 120-190mm;

Large bearings, bearings with a nominal outer diameter range of 200-430mm;

Extra-large bearings, bearings with a nominal outer diameter range of 440-2000mm;

Heavy-duty bearings, bearings with a nominal outer diameter range of 2000mm or more.

Miniature bearings refer to various types of bearings with a metric series and an outer diameter of less than 9mm, an inch series with an outer diameter of less than 9.525mm! The primary materials are carbon steel, bearing steel, stainless steel, plastic, ceramics, etc. The smallest inner diameter can be 0.6mm, and the inner diameter is generally 1mm. The smallest commercial bearing in the world can achieve this size: 1.5mm outer diameter, 0.5mm inner diameter, and six steel balls with a diameter of 0.25mm. Miniature bearings are as diverse as ordinary bearings. The most common miniature bearings are miniature roller bearings and miniature ball bearings. Miniature bearings are often called mini bearings or tiny bearings.

Miniature bearings are suitable for various industrial equipment, small rotary motors and other fields with high speed and low noise, such as office equipment, micro motors, instruments, laser engraving, small clocks, soft drives, pressure rotors, dental drills, hard disk motors, Stepper motors, video recorder drums, toy models, computer cooling fans, money counters, fax machines, and other related fields. Miniature bearings are as diverse as ordinary bearings. The most common miniature bearings are miniature roller bearings and miniature ball bearings. Miniature bearings are often called mini bearings or tiny bearings.

About 40% of the failures of miniature bearings are caused by dust, dirt, debris, and corrosion. Pollution is usually caused by improper use and reduced use environment. It can also cause torque and noise problems. The failure of miniature bearings due to the environment and pollution can be prevented, and the cause of such failures can be determined through simple visual inspection. As long as the use and installation are reasonable, the erosion of miniature bearings is natural to avoid. Decay is characterized by an indentation on the miniature bearing ring raceway caused by impact loads or incorrect installation. Erosion usually occurs when the load exceeds the material's yield limit. Corrosion can also happen if the amount is improperly installed so that a charge crosses the miniature bearing ring. The dents on the miniature bearing rings also generate noise, vibration, and additional torque. Miniature bearings are as diverse as ordinary bearings. The most common miniature bearings are miniature roller bearings and miniature ball bearings. Miniature bearings are often called mini bearings or tiny bearings.

Because the reasons for the heating of the miniature bearings are different, the solutions are different. The following are solutions when the temperature of the miniature bearings is too hot:

1. Regularly fill the bearing working surface with an appropriate amount of grease. This is the most commonly used method of grease lubrication. It is recommended to use professional miniature bearing grease for miniature bearings.

2. Set screw cap oil cup or pressure oil cup on the bearing seat. Rotate screw cap regularly or inject fat with oil gun. This is also a standard method of grease lubrication. It is recommended to use professional miniature bearing grease for miniature bearings.

3, is to rely on a grease pump to add oil to the miniature bearings. At this time, a fluid grease should be used.

4. Supply grease to each deep groove ball bearing and other components at the same time through a grease pump. Similarly, at this time, the oil should be selected from flowing oil, oxidation resistance, and antiseptic grease.

Hot Topics

Copyright © Wuxi Spark Bearings Co.,Ltd Co., Ltd All Rights Reserved. Sitemap

www.spark-bearing.com. Profession in Roller Bearings, Ball Bearings and Taper Toller Bearings-China Suppliers.