News

Detect The Tightness Of Bearing And Shaft Shoulder

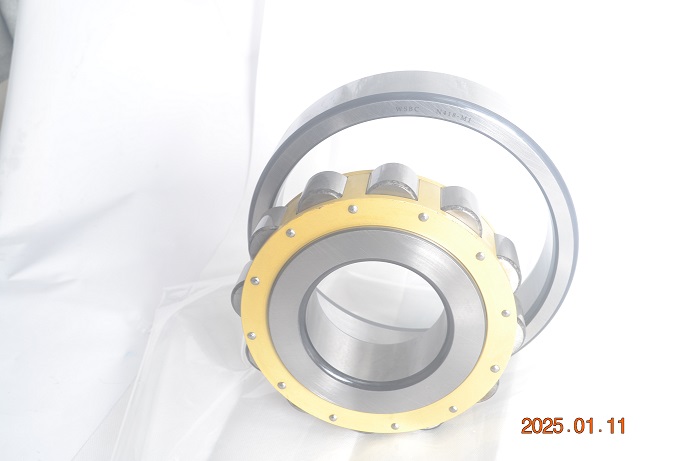

Time:2025.02.03 Source:Roller Bearings Suppliers

Testing method for tightness of rolling bearing and shaft shoulder

Generally speaking, rolling bearings with tight fit interference installation must be close to the shaft shoulder. So how to test it? According to our company's knowledge of bearings, let's share the detection methods of the tightness of rolling bearings and shaft shoulders. I hope that it will be helpful to everyone's bearing installation.

(1) Lighting method.

This method aligns the lamp at the bearing and shaft shoulder and judges according to the light leakage. If there is no light leakage, it means the installation is correct; if there is even light leakage around the shaft shoulder, it means that the rolling bearing is not close to the shaft shoulder, and pressure should be applied to the rolling bearing to make it close; if there is some light leakage, it means that the bearing installation is inclined, and a hand hammer or copper rod can be used Or the sleeve knocks on the inner ring of the bearing to gradually settle.

(2) Thickness gauge inspection method.

The thickness of the thickness gauge should start from 0.03mm. During the inspection, try to insert several places on the entire circumference of the bearing inner ring end face and the shaft shoulder. If there is a gap and it is very uniform, it means that the bearing is not installed in place. The bearing inner ring should be pressurized to make it close to the shaft shoulder; if it is enlarged The pressure is also not tight, indicating that the rounded corners of the rounded part of the journal are too large, and the bearing is stuck. The rounded corners of the journal should be trimmed to make it smaller; if it is found that the thickness of the end face of the bearing inner ring and the individual parts of the bearing shoulder can be Passed, it means that it must be disassembled, repaired, and reinstalled at this time. Click here for more details about WSBC N418-M1 .

If the bearing is installed in the bearing housing hole with an interference fit, when the outer ring of the bearing is fixed by the housing hole shoulder, whether the end face of the outer ring is tight with the housing hole shoulder end and whether the installation is correct can also be checked with a thickness gauge.

Such as inspection after installation of thrust bearing

When installing the thrust bearing, check the verticality of the shaft ring and the shaft centerline. The method is to fix the dial indicator on the end surface of the case and make the indicator's contact rest on the raceway of the bearing shaft ring while rotating the bearing while observing the dial indicator pointer. When the box shell-hole is deep, it can also be inspected with an extended dial gauge.

When the thrust bearing is installed correctly, its seat ring can automatically adapt to the rolling of the rolling elements to ensure that the rolling elements are located in the upper and lower ring raceways. If it is installed backward, the bearing will not work properly, but the mating surfaces will be severely worn. Since the difference between the shaft ring and the seal ring is not very obvious, you should be extra careful during the assembly and make no mistake. In addition, there should be a gap of 0.2-0. 5mm between the seat ring of the thrust bearing and the bearing seat hole to compensate for the errors caused by inaccurate parts processing and installation. When the center of the bearing ring is shifted during operation, This gap can ensure its automatic adjustment, avoid touching and rubbing, and make it operate normally. Otherwise, it will cause severe damage to the bearing. Wuxi Spark Bearing LTD provides high-quality WSBC NU322-E-M1-C3 .

When the flexible bearing of the harmonic reducer is assembled on the elliptical cam of the wave generator, there is a large pre-stress and pre-deformation. Under the actual working load, pre-stress and pre-deformation, the inner and outer ring of the flexible bearing are analyzed, and its deformation, stress and load distribution law are obtained.

(1)The deformation of the inner and outer rings of the flexible bearing mainly depends on the contour line of the wave generator cam. The radial deformation of the inner ring is the largest at the long axis, and the radial deformation at the short axis is the smallest, which is close to 45. Where the deformation is 0. The radial deformation of the outer ring is similarly distributed. The pre-deformation of the outer ring is 0 in the circumferential direction at the major axis and the minor axis and is nearly 45. Is the maximum value, and the analysis result accords with the thin-walled ring theory. The maximum deformation of the inner ring is slightly larger than that of the outer ring. This is due to the contact deformation between the rolling elements and the inner and outer rings, and there is a certain amount of approach.

(2) After the flexible bearing is assembled to the elliptical shaft cam, the maximum prestress of the inner and outer rings is the largest at the major axis of the ellipse, and the maximum prestress of the inner ring is larger than that of the outer ring. This is mainly because the radius of curvature of the inner ring is larger than that of the outer ring. small. The bending stress is relatively large, which is consistent with the bending theory in material mechanics.

(3)Considering the prestress, under the same radial load, the equivalent stress of the inner and outer rings of the flexible bearing has a larger increase than the equivalent stress without considering the prestress, which has a greater impact on the rated load capacity of the flexible bearing. Big impact.

(4) According to the L-P theory, the fatigue life of the flexible bearing is accurately calculated. The results show that the fatigue life of the flexible bearing is reduced by 30% when the prestress is considered. This puts forward higher requirements for the design and manufacture of the flexible bearing for the harmonic reducer.

Wuxi Spark Bearing Co., Ltd (Aka Spark Bearings) is the complete, one-stop spherical roller bearings, supplier & manufacturer. All products are qualified and have passed the ISO 9001 qualification. Here are some popular types of bearings, Send a quote and get the latest price of cheap bearings from Spark Bearings.

Hot Topics

Copyright © Wuxi Spark Bearings Co.,Ltd Co., Ltd All Rights Reserved. Sitemap

www.spark-bearing.com. Profession in Roller Bearings, Ball Bearings and Taper Toller Bearings-China Suppliers.