News

Basic Performance Requirements of Steel for Rolling Bearings

Time:2025.02.21 Source:Roller Bearings Suppliers

The performance of rolling bearings

In the actual use of rolling bearing parts, they often have to work at high speed for a long time under complex stress states such as stretching, compression, bending, shearing, alternating and high-stress values. Whether the materials used to manufacture rolling bearings are suitable or not will have a great impact on their service performance and life.

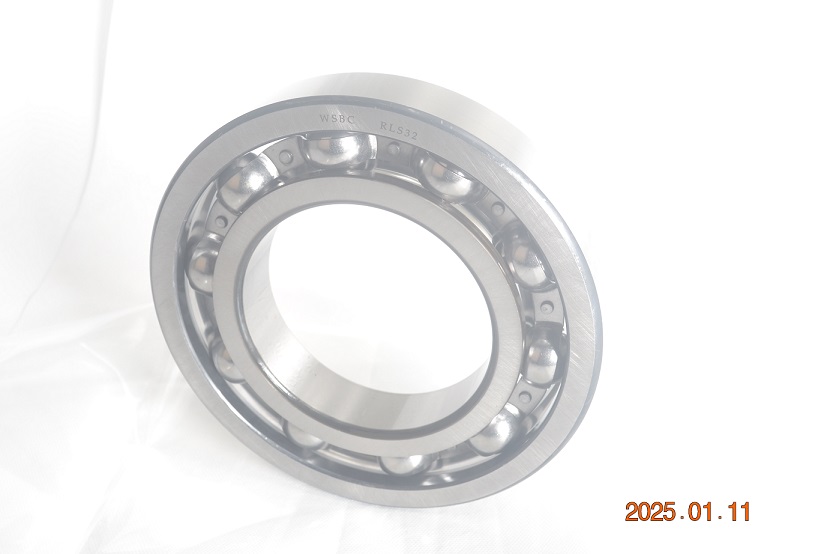

The basic method of selecting materials is decided according to the failure (failure) form of bearings. In general, the main damage form of rolling bearings is fatigue stripping under the action of alternating stress, as well as the loss of accuracy of bearings due to friction and wear, in addition, there are cracks, pressure pits, rust and other reasons for the abnormal damage of bearings. Therefore, in general, rolling bearings should have high resistance to plastic deformation, less friction and wear, good rotation accuracy, high dimensional accuracy, good dimensional stability, and long contact fatigue life. And many of these properties are determined by the material and the heat treatment process. Therefore, it is required that the materials for the manufacture of rolling bearings have the following properties after certain heat treatment in the post-process. Need WSBC RLS32, click here to learn more.

1. High contact fatigue performance

When the rolling bearing is running, when the rolling body rolls between the raceway of the inner and outer rings of the bearing, the contact part bears periodic alternating loads, which can reach tens of thousands or hundreds of thousands of times per minute. Under the repeated action of periodic alternating stress, the contact surface appears fatigued spalling. After the beginning of spalling, the vibration and noise of the bearing will increase, and the working temperature will continue to rise, resulting in the final fatigue damage of the bearing and the failure to use it. Contact fatigue failure is the main failure form of rolling bearings. Therefore, it is required that the steel used for rolling bearings should have high contact fatigue strength.

2. High wear resistance

When the rolling bearing is working normally, in addition to rolling friction, there is sliding friction. The main parts of sliding friction are the contact surface between the rolling body and the raceway, the contact surface between the rolling body and the cage pocket, the contact surface between the cage and the ring guide guard, the contact surface of the end face of the roller and the ring guard. The existence of sliding friction in rolling bearings inevitably causes wear and tear of bearing parts. If the wear resistance of bearing steel is poor, the rolling bearing will lose the accuracy of the bearing prematurely because of wear or increase the vibration of the bearing and decrease the life of the bearing because of the decline of the rotating accuracy of the bearing. Therefore, bearing steel is required to have high wear resistance.

3. High elastic limit

Rolling bearing is working, due to the contact area between the internal and external ring, the roller is small, bearing, especially under high load when the load cases, contact surface contact stress is large, in order to prevent occur plastic deformation under high contact stress, so that the damaged bearing precision and surface cracks, so should have a high elastic limit of bearing steel.

4. Appropriate hardness

Hardness has a very close relationship with contact fatigue life, wear resistance and elastic limit, so the hardness of rolling bearings also directly affects the life of rolling bearings, so hardness is one of the important indicators of rolling bearings. The hardness of rolling bearings is usually determined by the way and size of the bearing load, the bearing size, and the wall thickness of the overall situation, and the hardness is too high or too low will affect the life of the bearing. As is known to all, the main failure forms of rolling bearings are contact fatigue Fatigue damage; Poor wear resistance or dimensional instability resulting in the loss of bearing accuracy;

Bearing parts lack a certain toughness, under the larger impact load and brittle fracture resulted in the destruction of the bearing. The hardness of the bearing must be determined according to the specific situation of the bearing and the way of failure. For the loss of bearing accuracy due to fatigue spalling damage or poor wear resistance of bearing parts, bearing parts should choose higher hardness; For bearings that bear large impact loads (e.g. rolling) Machine bearings, some automobile bearings, etc.), it is necessary to appropriately reduce the hardness to improve the toughness of bearings.

5. A certain amount of toughness

Many bearings bear a certain impact load in the process of use, so the bearing steel is required to have a certain toughness to ensure that the bearing is not damaged due to the impact load. For bearings bearing large impact loads, such as rolling mill bearings, railway bearings and other required materials with relatively high impact toughness and fracture toughness, some of these bearings are quenched by bainite, some are carburized steel, to ensure that these bearings have good impact resistance.

6. Good dimensional stability

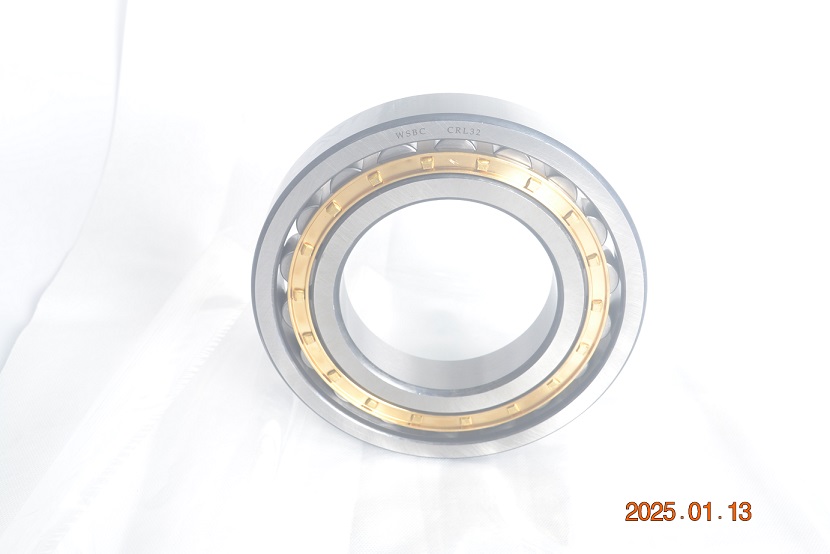

Rolling bearings are precise mechanical parts, whose accuracy is measured in microns. In the long-term storage and use of bearings, the accuracy of bearings should not be lost due to the change of bearing size caused by the change of internal organization or stress of bearing parts. Therefore, the bearing steel is required to have better dimensional stability. Click here to learn more about WSBC CRL32.

7. certain rust resistance

Because of the various production processes of rolling bearings and the long production cycle, some semi-finished products or finished parts need a longer time to be stored before assembly. Therefore, bearing parts are easy to rust in the production process or in the preservation of finished products, especially in the humid air. Therefore, steel for rolling bearings is required to have a certain anti-rust performance.

8.Good process performance

Rolling bearing in the process of production, the parts need to pass more than cold and hot working process, which requires the bearing steel should have good processing property, such as cold and hot forming performance and machining performance, the performance of grinding, heat treatment performance, etc., to adapt to the rolling bearing large quantity, high efficiency, low cost, and high-quality production needs. In addition, forbearing steels used under special working conditions, in addition to the above basic requirements, they should also have corresponding special performance requirements, such as high-temperature resistance, high-speed performance, corrosion resistance and non-magnetic property.

Wuxi Spark Bearing Co., Ltd (Aka Spark Bearings) is the complete, one-stop Spherical roller bearings, supplier & manufacturer. All products are qualified and have passed the ISO 9001 qualification. Here are some popular types of Spherical roller bearings, Send a quote and get the latest price of cheap bearings from Spark Bearings.

Hot Topics

Copyright © Wuxi Spark Bearings Co.,Ltd Co., Ltd All Rights Reserved. Sitemap

www.spark-bearing.com. Profession in Roller Bearings, Ball Bearings and Taper Toller Bearings-China Suppliers.