News

Cleaning And Installation Of WSBC Bearing

Time:2020.09.09 Source:Roller Bearings Suppliers

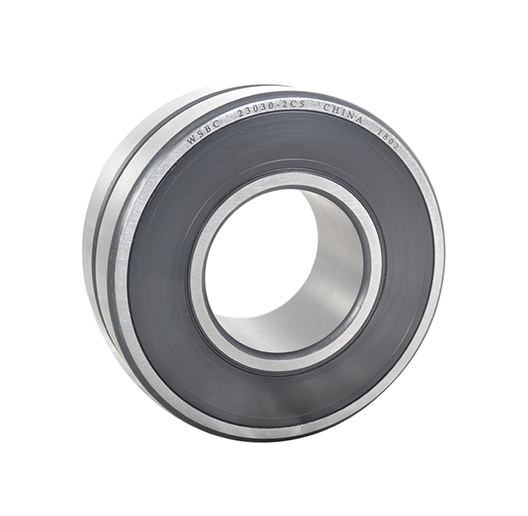

Most of the newly bought WSBC bearings are coated with grease. These greases are mainly used to prevent WSBC bearings from rusting and do not provide lubrication. For example,WSBC 23030-2CS.Therefore, they must be thoroughly cleaned before they can be installed and used. The cleaning method is: all WSBC bearings sealed with anti-rust oil can be cleaned with gasoline or kerosene. For WSBC bearings that use heavy oil and anti-rust grease, such as industrial petroleum jelly, can be heated to dissolve and clean with engine oil or transformer oil (the oil temperature should not exceed 100°C), and then immerse the WSBC bearings in the oil. After the anti-rust grease is melted and taken out to cool, clean it with gasoline or kerosene.

For WSBC bearings that are inconvenient to disassemble, they can be flushed with hot oil. That is, use hot engine oil at a temperature of 90°-100°C to dissolve the old oil. Use an iron hook or a small spoon to dig out the old oil in the WSBC bearing, and then use kerosene to flush out the remaining old oil and engine oil inside the WSBC bearing. Finally, flush it with gasoline.Wuxi Spark Bearing Co.,Ltd provides Spherical roller bearings 23030-2CS, cilck here for more details.

The cleaning quality of WSBC bearings is tested by hand feeling. After cleaning the WSBC bearing, carefully observe that there will always be some remaining oil in the inner and outer ring raceways, on the rolling elements and in the gaps of the cage. During inspection, use a clean feeler gauge to scrape out the remaining oil and apply it to the thumb. Use your index finger to slowly rub back and forth. If there is a rustle between your fingers, it means that the WSBC bearing has not been cleaned and you should wash it again. Finally, hold the WSBC bearing in your hand, pinch the inner ring, and rotate the outer ring horizontally (large WSBC bearings can be placed on the assembly table, the inner ring is cushioned, the outer ring is suspended, the inner ring is compressed, and the outer ring is rotated), Qualified for flexible rotation, no blocking, and no beating. The cleaned WSBC bearings should be filled with lubricant and placed on the assembly table, with a clean cloth or paper pad underneath, and a plastic cloth on the top for assembly. It is not allowed to be placed on the ground or box. When moving the WSBC bearing, it is not allowed to hold it by hand. You should wear canvas gloves or wrap the WSBC bearing with a clean cloth before picking it up. Otherwise, sweat and moisture on your hands may cause fingerprints and rust on the WSBC bearing after contact. For WSBC bearings with dust caps or sealing rings on both sides, and WSBC bearings coated with anti-rust and lubricating grease, since the grease has been injected during manufacturing, do not clean them before installation.

Cleaning of shaft and WSBC bearing housing housing holes and other parts. First clean with gasoline or kerosene, wipe with a dry cloth, and then apply a small amount of oil to facilitate installation. After cleaning these parts, it should be noted that all casting sand on the castings should be completely removed; any burr and sharp corners on the parts matching with the WSBC bearing must be removed to prevent residual sand and metal chips from falling into the WSBC bearing during installation. Affect assembly quality.

Installation Method

1.Use copper rods and manual strike installation

This is an easy way to install small and medium WSBC bearings. When the inner ring of the WSBC bearing has a tight fit and the outer ring has a loose fit, put the copper rod close to the end face of the inner ring of the WSBC bearing, directly hit the copper rod with a hammer, and transfer the force through the copper rod to slowly install the WSBC bearing on the shaft . When the inner ring of the WSBC bearing is large, you can use a copper rod to strike evenly around the end face of the inner ring of the WSBC bearing. Do not strike only one side or excessively. The symmetrical strike should be used. Gently strike and install slowly to avoid oblique strikes. Split WSBC bearings.

When the outer ring of the WSBC bearing has a tight fit and the inner ring has a loose fit, the opposite method can be used to knock the copper rod close to the end face of the outer ring with a hand hammer to press the WSBC bearing into the WSBC bearing seat. Installed on the shaft, this method is not easy to damage the parts.

2.Use sleeve to install

This method is the same as using copper rods to install WSBC bearings. It presses the sleeve directly on the end face of the WSBC bearing (the end face of the inner ring is pressed when the WSBC bearing is installed on the shaft; the end face of the outer ring is pressed when installed in the housing hole), and the striking force of the hand hammer can be evenly distributed It is installed on the end face of the entire ring of the WSBC bearing, and can be used in conjunction with a press, which saves effort and time in installation and has reliable quality.

The sleeve used for installation should be made of soft metal (copper or low-carbon steel pipe can be used). If the WSBC bearing is installed on the shaft, the inner diameter of the sleeve should be slightly larger than the journal 1-4mm, and the outer diameter should be slightly smaller than the rib diameter of the inner ring of the WSBC bearing, or the thickness of the sleeve shall be the same as that of the WSBC bearing 2/3-4/5 of the ring thickness, and both ends of the sleeve should be flat and perpendicular to the barrel. If the WSBC bearing is installed in the seat hole, the outer diameter of the sleeve should be slightly smaller than the outer diameter of the WSBC bearing.

When installing WSBC bearings with sleeves, if the parts are small, they can be installed on a vise. The jaw pads are made of copper or aluminum to prevent the shaft from being pinched. If the machine is large in size, it should be installed on a wooden frame. Install the WSBC bearing on the shaft first, then install the sleeve, and then evenly knock the sleeve with a hand hammer to install it slowly. When the sleeve end cover is flat, the hand hammer should strike the sleeve evenly along its circumference.WSBC 23120-2CS online, contact us for more details.

3.Press-in method

The installation pressure should be directly applied to the end face of the WSBC bearing ring with interference fit, otherwise it will cause crushing on the working surface of the WSBC bearing and cause the WSBC bearing to be quickly damaged.

4.Heating installation

For installation of WSBC bearings or large-size bearings with large interference, in order to facilitate the installation, the principle of thermal expansion and contraction can be used to install the WSBC bearing in the oil tank with a copper rod, sleeve and hand hammer. The temperature during heating is generally controlled below 100°C, and 80-90°C is more appropriate. When the temperature is too high, it is easy to cause annealing of the WSBC bearing ring raceways and rolling elements, which affects the hardness and wear resistance, resulting in a reduction in the life of the WSBC bearing and premature scrapping.

When using the oil tank to heat the WSBC bearing, there should be a grid at a certain distance from the bottom of the box, or the WSBC bearing should be hung with a hook. The WSBC bearing cannot be placed on the bottom of the box to prevent precipitated impurities from entering the WSBC bearing or uneven heating. The oil tank must be There is a thermometer to strictly control the oil temperature not to exceed 100°C to prevent the occurrence of tempering effects and reduce the hardness of the ferrule. After the oil temperature reaches the specified temperature for 10 minutes, quickly remove the WSBC bearing from the oil and install it on the shaft while it is hot. If necessary, you can use the installation tool to apply a little pressure on the end face of the WSBC bearing inner ring, which makes it easier to install. After the WSBC bearing is installed on the shaft, the inner ring must be pressed immediately until it cools down.

Wuxi Spark Bearing Co., Ltd. has more than ten years of experience in bearing export. Customers in more than 50 countries and regions around the world. In so many years of continuous development, we continue to improve the quality of our products. But we also ensure that the price is competitive among peers. Looking forward to cooperating with more customers in the future to establish long-term trade relations.

Hot Topics

Copyright © Wuxi Spark Bearings Co.,Ltd Co., Ltd All Rights Reserved. Sitemap

www.spark-bearing.com. Profession in Roller Bearings, Ball Bearings and Taper Toller Bearings-China Suppliers.