News

Causes Of Heating When WSBC Bearings Are Used

Time:2021.04.21 Source:Roller Bearings Suppliers

The cause of overheating of imported WSBC bearings may be incorrect installation. The skewed installation will cause the balls not to roll in the correct position of the bearing raceway, and even cause larger ball end faces and the axial direction of the inner race and outer race stop of the WSBC bearing housing. Force, causing the bearing to overheat.

There is another possibility that the measurement of the shaft diameter and the size of the bearing seat hole is inaccurate or the mating surface roughness does not meet the standard requirements, resulting in an excessive interference fit, causing the bearing race to be greatly squeezed, resulting in the WSBC bearing itself The radial clearance of the WSBC bearing is reduced, which makes the WSBC bearing difficult to rotate, heats up, wears out or gets stuck, and in severe cases, it will cause the inner and outer races of the bearing to be installed.

Wuxi Spark Bearing Co., Ltd provides WSBC 24026-2CS. Click here for more details.

Lubrication method of WSBC bearings

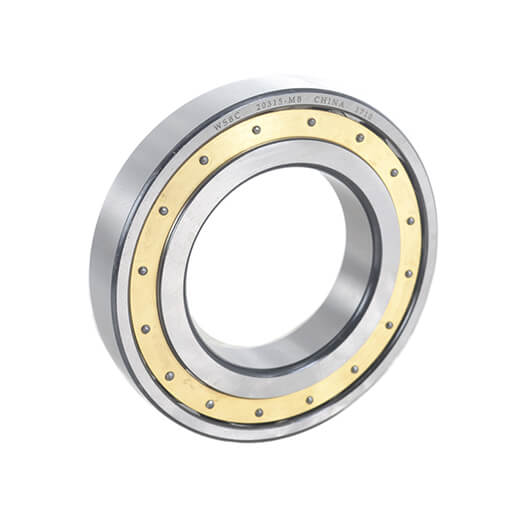

The anti-friction bearings in all WSBC bearings basically consist of two hardened steel rings, a number of hardened balls or rollers, and a separate frame or cage to separate the rollers or rollers. These types are divided into many types in use. Some types, such as needle cylindrical bearings, may not have an inner ring, and the rollers move directly on the hardened shaft.

Maintenance method of WSBC imported bearings

In practice, it is necessary to use more than the recommended amount of grease. When the required torque is low, only very little grease is needed to lubricate the bearing. When the speed is very low and the WSBC bearing is exposed to dust or moisture, the bearing may almost be filled. Bearings generally require more frequent lubrication at high speeds and high temperatures than under normal conditions.

Click here for more details about WSBC 24030-2CS.

Although the quality of WSBC bearings is relatively good in all aspects, rolling bearings are precision parts, and their use must be carried out accordingly. No matter how high-performance WSBC bearings are used, if they are used improperly, the expected high performance will not be obtained. There are several precautions concerning the use of WSBC bearings:

(1) Keep the WSBC bearing and its surroundings clean

Even small dust invisible to the eyes will have a bad effect on WSBC bearings. Therefore, it is necessary to keep the surroundings clean to prevent dust from entering the WSBC bearing.

(2) Use it with caution

A strong impact on the WSBC bearing during use will cause scars and indentations, which may cause accidents. In severe cases, it will crack or break, so be careful.

(3) Use appropriate operating tools

Avoid replacing existing tools, you must use appropriate tools.

(4) Pay attention to the corrosion of WSBC bearings

When handling WSBC bearings, sweat on your hands can become a cause of rust. Pay attention to the operation with clean hands, it is best to wear gloves as much as possible.

(5) The heat radiates to the surroundings

To guide the magnet, the induction coil is placed on insulating paint and glass fiber cloth, etc. This form of heat loss is small, the heat is evenly received, and has little effect on sensor burnout.

(6) The heat of cooling water

This part of the heat dissipation cools the sensor, enabling the safe operation of induction heating. The study found that at 0-180 degrees, low water temperature intake indicates good heat exchange cooling water, the water is smooth, and there is no water temperature; because of the length of the flow path, the water temperature rises, and the water temperature rises, causing heat Exchange changes because the sensor can easily cause the temperature of a site to rise, which is the main induction coil burning.

(7) The heat transfer plate of the induction coil

the current density of part of the plate, the large cross-section and the low water temperature, the area of the heat transfer plate in the area, the coil of the heat transfer plate. The part of 0 to 90 degrees and 270 -360 degrees is far away from the nearby induction coil plate, which has good thermal conductivity; away from the plate, the thermal conductivity is poor. The 90 to 270 pieces of induction coils make the larger induction coil temperature in this area easy to appear in this part Appears like burned coils. The heat flow of the induction coil is compared in different parts. The thermal induction loop in the area near 225 degrees, and has carried out the savings, so the area is prone to large differences between the induction coil burning phenomenon.

Wuxi Spark Bearing Co., Ltd (Aka Spark Bearings) is the complete, one-stop Roller Bearings supplier & manufacturer. All products are qualified and have passed the ISO 9001 qualification. Here are some popular types of Angular Contact Ball Bearings, Send a quote and get the latest price of cheap bearings from Spark Bearings.

Hot Topics

Copyright © Wuxi Spark Bearings Co.,Ltd Co., Ltd All Rights Reserved. Sitemap

www.spark-bearing.com. Profession in Roller Bearings, Ball Bearings and Taper Toller Bearings-China Suppliers.