News

Bearing performance requirements and quality inspection of bearing operation

Time:2021.02.24 Source:Roller Bearings Suppliers

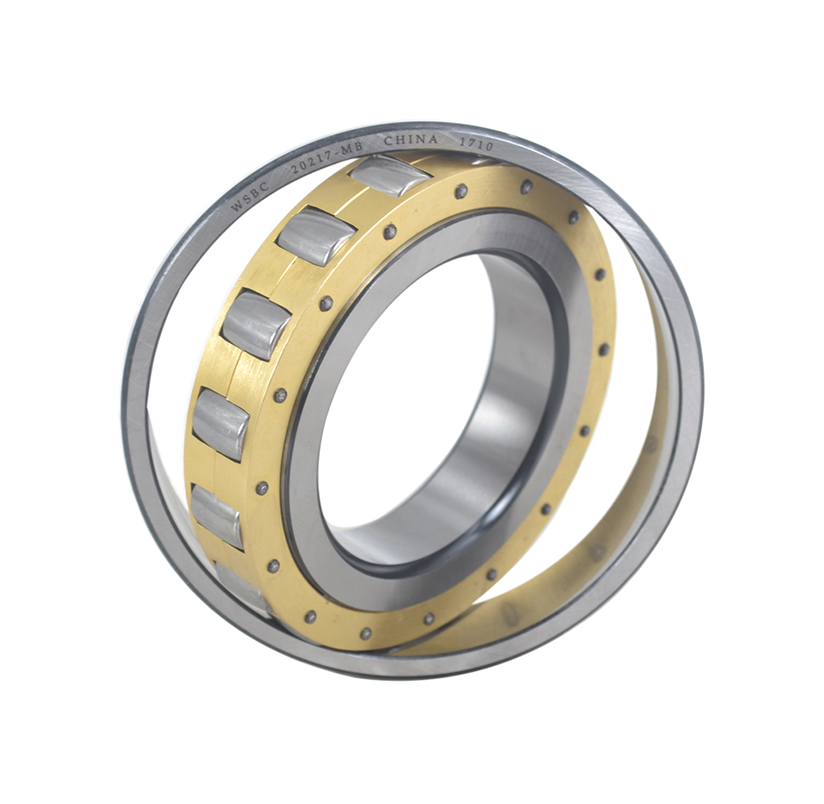

Overview of bearings

The bearing is composed of an inner, outer ring, a rolling body (ball, roller or roller) and the holder's four parts, and the rest are composed of bearing steel in addition to the holder. When the bearing is working, the bearing, the outer ring, and the bearing rolling body have a high frequency and becoming effective. The working conditions of the bearing are very complicated. The load is concentrated on a small area of the rolling bodies. In theory, the ball is in a point; and for the roller, the roller is active and the inter-contact area between the rolling bodies and the ferrule is also small (present, and therefore, the bearing part is working, The unit area of the rolling bodies and ferrules should bear great pressure.

Performance requirements for bearings

The life and reliability of the bearing correspond to the design, processing, lubrication conditions, installation, maintenance, etc., but the high quality and reliability of the bearing material are key. The rolling bearing part operates at high speed and time in a complex stress state and high-stress value such as stretching, compression, bending, shear, alternative. Therefore, the requirements for the rolling bearing:

1. High resistance to plastic deformation,

2. High anti-friction, wear performance,

3. High rotation accuracy and dimensional accuracy,

4. Good dimensional stability,

5. Long service life and high reliability.

Bearing operation quality check

After the bearing is installed, it should be checked. It should ensure that the bearings are installed in place, the rotation is flexible, no cardiosity, such as improper bearings, which will cause the bearing temperature to rise rapidly and damage, and even a bearing card is broken. WSBC 623-2RS bearings online, pls click here.

1. Detect the bearing

Refracture of the rotation of the bearing, the sound, such as the sound, etc., has strong metal noise, abnormal sound, irregular sound, etc. Its reason is poorly lubricated, the shaft or bearing sector is poor, bearing damage, foreign body invasion, etc.

2. Check the bearing temperature

The temperature of the bearing generally speculates according to the external temperature of the bearing housing. However, the temperature of the bearing outer ring is more accurately measured by the oil hole. The bearing temperature is gradually increased from the start of the operation, and the temperature is stable after 1 to 2 hours. If the bearing is not installed, the temperature will rise sharply and abnormally high temperature. The reason, such as too much lubricant, too small the bearing swap, no installation, and the sealing device is too large. It is also why the bearing structure, and the choice of bearing structure, and lubrication.

3. Confirm that the bearing is rotated smoothly

Small machinery can be rotated with a hand to confirm whether it is smooth. Checking the project has no operation due to foreign objects, scars, indentations, and the torque generated by the poor installation, the mounting processing is unstable. Due to the overshoot, the mission caused by the mounting error, the sealing friction is too large. Wait. If there is no abnormality, the power operation can be started.

4. Check if there are other abnormalities

The large machines cannot be manually rotated, so the power is turned off immediately after the air is activated, and the mechanical is idling, check whether there is vibration, noise, rotating components, etc., confirm that there is no abnormality, enter the power operation.

Wuxi Spark Bearing Co., Ltd is the complete, one-stop bearings supplier & manufacturer providing high-precision roller bearings, ball bearings, tapered roller bearings OEM, sales and service. Here are some popular types of deep groove ball bearings, Send a quote and get the latest price of cheap bearings from Spark Bearings.

Hot Topics

Copyright © Wuxi Spark Bearings Co.,Ltd Co., Ltd All Rights Reserved. Sitemap

www.spark-bearing.com. Profession in Roller Bearings, Ball Bearings and Taper Toller Bearings-China Suppliers.