News

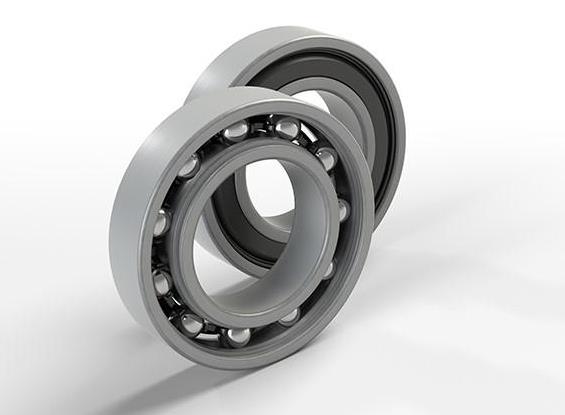

Quality analysis and judgment after bearing assembly

Time:2021.02.24 Source:Roller Bearings Suppliers

The quality indicators of the bearing assembly are mainly: general requirements, accuracy tolerances, extensive values, vibration and noise, filling amount, etc. Among them, the appearance quality and rotation flexibility is a qualitative indicator, which requires the constant accumulation of experience to achieve a high judgment analysis level.

Dimensional accuracy is extremely different

Inner diameter, the outer diameter size is possible in the finished inspection, main reasons:

1. Product leak inspection of the front process.

2. Assembly check environment temperature difference changes.

3. Standard parts and ferrules are not sufficient.

4. Willing and finished product check use standard parts unqualified.

The inner diameter of the bearing is too large, and it should be sentenced to unqualified products, and the inner circle will be scrapped. The inner diameter is too small, and it should be unqualified by unqualified products, but it can be repaired to make it a qualified product. The outer diameter of the bearing is too large, which can be evident by re-grinding. However, the outer diameter is too small and should be sentenced to unqualified bearings, and the outer ring will be scrapped.

Rotation accuracy is extremely different

The reason why the rotation accuracy is extravasation is:

1. When the ferrule is grinding, the channel center is facing the benchmark end face equality.

2. There is a wound on the surface of the inside and outside, with dirt.

3. The inside and outside ferrule are hurt.

4. The internal and external channel diameter variable is large.

5. When the last goal is loaded, the outer ring will be deformable, or the steel ball is hurt.

6. It may be equipped with a mixed bill, and the steel ball is too large.

7. Capture deformation.

8. Ditch shape deformation.

KIA and KEA are extremely bad, even if it is due to the difference between the cells of the individual ferrule on the inner diameter or outer diameter thickness. However, SIA and SEA are extremely disadvantaged. In order to reduce losses, it is often improved by re-combining assemblies through disassembly. SD and SD are only scrapped. WSBC 3200A-2RS bearings online, pls click here.

Bearing flexibility is not good

The bearing flexibility is not good, the main reasons are:

1. The inside of the bearing into the contamination during riveting.

2. The pressure is too heavy during riveting so that the casing is deformed.

3. The mold is uneven so that the casing is compressed uneven, deformation is generated.

4. The diameter of the rivet is out of diameter, and the length is extremely different, and when the riveting is riveted, the same retention rivet deformation amount is not equal to the retaining.

5. The retaining spherical dimension is extremely devastating so that the steel ball is rotated without a sufficient radial gap.

6. The radial gap is too small when combining.

7. Individuals are mixed with big spheres, can't rotate.

Radial clearance

In the case of the radial gap, the radial clearance is extraordinary, the main reasons are:

1. The numerical value of the ferrule size is inaccurate, due to the occasional errors in the sorting, the measurement system error is caused.

2. The numerical value of the ferrule size is inaccurate, due to the occasional errors in the sorting, the measurement system error is caused.

3. The radius of cascade channel curvature is extremely different.

4. Measuring the axial swap, the steel ball is equal, the position is incorrect, the hand thrust is inconsistent.

5. The bearing is not clean enough.

6. The ferrule channel geometric dimension is too large.

7. The center of the holder is too large.

Excessive clearance and too small are unqualified products. But you can rework, re-matching to achieve a qualified tour.

Bearing rust

The bearing rust is unqualified in appearance quality. It is caused by improper storage of bearing parts; the anti-rust process is not strict during assembly; especially the plum rain season operator without gloves; the air relative wetness between assembly operations is large; poor cleanliness.

Wuxi Spark Bearing Co., Ltd is the complete, one-stop bearings supplier & manufacturer providing high-precision roller bearings, ball bearings, tapered roller bearings OEM, sales and service. Here are some popular types of ball bearings, Send a quote and get the latest price of cheap bearings from Spark Bearings.

Hot Topics

Copyright © Wuxi Spark Bearings Co.,Ltd Co., Ltd All Rights Reserved. Sitemap

www.spark-bearing.com. Profession in Roller Bearings, Ball Bearings and Taper Toller Bearings-China Suppliers.