News

Adjustment Of Spindle Bearing And Drive Shaft Bearings

Time:2019.12.24 Source:Roller Bearings Suppliers

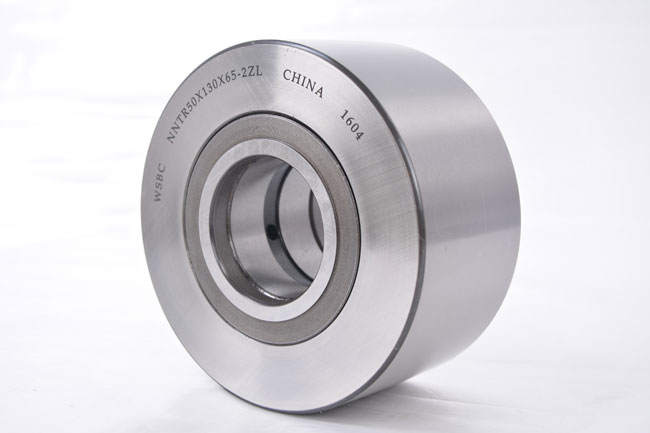

Spindle bearing adjustment, lathes, grinders, and milling machines have hollow thin-walled spindles with front and rear sets of bearings. The front end of the axle is mostly a conical hollow single-row or double-row radial short cylindrical bearing. So how to adjust it during installation and maintenance?

For example, C620-1 lathe spindle bearing adjustment method, the front end of the lathe's main shaft is equipped with 3182120 bearings, and the inner ring of the bearing is pushed by the adjusting nut on the rod to adjust the axial movement along with the tapered journal of the main shaft to control the radial direction.

The amount of runout, sometimes when the bearing is moved axially, the inner tapered hole and the leading shaft taper do not coincide, which causes the inner ring raceway to be distorted along the axis, which causes the bearing to heat up and reduce accuracy, which needs to be avoided. When adjusting, the speed should be adjusted slowly, not too much. It is best to use a meter to measure the radial runout of the journal to turn lightly without resistance by hand.

If the temperature is too high, you can open the front cover and use copper rods to gently tap the bearing inner ring symmetrically around it, so that the tapered surface overlaps with the end face of the adjusting washer. The 180 ° or 90 ° phase adjustment can be used to improve the radial runout.

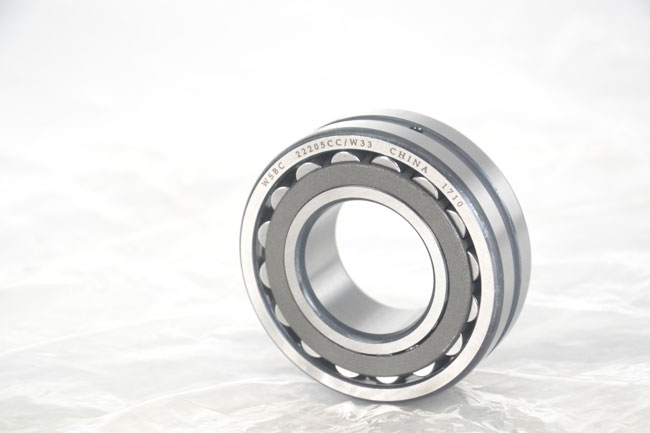

The bearings of the other shafts in the headstock are mostly single-row tapered roller bearings. Since this type of bearing will cause instability in the temperature state after preloading, this bearing must leave a gap. When adjusting, it is necessary to adapt to an appropriate clearance that is compatible with the maximum speed of the machine tool and pay attention to disengaging the adjustment of each axis and the engaging shaft to avoid interference.

When the bearing clearance is too large or too small, it can be adjusted with the adjusting screw. The amount of axial movement should be controlled within 0.02mm, and the gap between the main shaft and the bearing can be controlled within 0.01mm.

The adjustment of the main shaft sliding bearing is described in two forms of M7120A flat grinding main shaft bearings. Alignment of little three-watt sliding bearings. When adjusting this type of bearing, a process sleeve is required. At the time of manufacture, the inner diameter of the process sleeve is 0.04 mm more significant than the primary shaft diameter, and the outer diameter is 0.005 mm smaller than the inner hole of the housing.

When adjusting, use the technology sleeve to make the adjustment screws of the three bearing shells uniformly. Use a 0.02mm feeler gauge to insert and check around the two holes in the front and back of the technology sleeve.

It is required that the feeler gauge can be added around the spindle and the spindle, and A gap of 0.005-0.01mm is maintained between the "short three-watt" sliding bearings. When measuring the hole, dial the dial indicator on the journal and lift the front end of the main shaft up and down by hand. The reading difference of dial indicator is the allowable gap value. The axial movement is within 0.01mm. Turning the spindle by hand should be light and unobstructed.

Regarding adjustment of the integral plain bearing. When the plain bearing is essential, the clearance is mainly adjusted by the thickness of the front washer of the main shaft. The adjustment method is to give 3 kg of thrust backward, note the reading on the rear end surface of the spindle, remove the front washer, reinstall the axle into the sliding bearing hole, and measure the force again. The difference between the two readings should be 0.15mm, and the gap at this time is 0.005mm. If it is higher than 0.005mm, the gap can be adjusted by the gasket.

Pay attention points for adjusting sliding bearings. The radial clearance is required to be very small. The consent can be changed twice. In the beginning, the gap is adapted to be more significant. After a certain period of operation, the temperature rise is healthy and then adjusted to the required gap amount. The lubricant should meet the requirements — cold and hot gap variation. The temperature rises below forty degrees is 0.005-0.01mm.

After adjusting the gap amount in the raw state, the gap amount in the hot state should not be measured. Generally, the temperature rise of the test run shall not exceed 1820 ℃ at room temperature. Shafts and plain bearings should meet specific accuracy requirements and be well balanced. You can drive by turning the main shaft without resistance.

Copyright © Wuxi Spark Bearings Co.,Ltd Co., Ltd All Rights Reserved. Sitemap

www.spark-bearing.com. Profession in Roller Bearings, Ball Bearings and Taper Toller Bearings-China Suppliers.