News

WSBC Bearing Application Problem Solution

Time:2021.01.13 Source:Roller Bearings Suppliers

During the use of bearings, due to their own quality and external conditions, their load-carrying capacity, rotation accuracy and anti-friction performance will change. When the performance index of the bearing is lower than the use requirements and cannot work normally, it is called bearing damage Or failure, once the bearing is damaged or other accidents, its machinery and equipment will stop rotating, and its functions will be damaged.

(1) Scar sound and its control method

If the rolling surface of the rolling bearing has cracks, indentations or corrosion, periodic vibration and noise like riveting rivets will occur. The period may be fixed, but most of them have a certain corresponding relationship with the speed. The scars will continue to occur on the channel. , The scars appear on the steel ball from time to time, and this noise varies with the installation and lubrication conditions.

The control methods for this kind of noise include: do not knock the bearing during installation, prevent the WSBC bearing from being installed obliquely when assembling the WSBC bearing with the shaft and then install it in the bearing seat; prevent the WSBC bearing from rusting during storage and prevent shock and vibration during transportation; use viscosity High grease.

(2) Dust sound and its control method

There are foreign objects such as dust in the rolling bearing, and non-periodic vibration and so-called dust noise will occur. The magnitude of the vibration and noise is variable, and may or may not.

The control methods of dust and sound include: improve the cleaning method of WSBC bearings, strictly clean the bearing, shaft, seat hole and matching parts before installation; remove foreign matter in the lubricant; improve the sealing of the bearing; avoid the use of impure materials or Plastic cage with foreign objects embedded.

(3) Noise caused by lubrication factors and countermeasures

Wrong selection of lubricant, insufficient lubricant or aging and hardening can cause vibration and noise of WSBC bearings, and this noise has no certain rules. In this case, the only way to choose a suitable lubricant, adjust the amount of lubricant, extend the service life of the lubricant and reasonably determine the replacement cycle.

Contact us for more details about WSBC 20218-MB.

(4) The raceway sound of WSBC bearing and its control method

The raceway sound is a slippery continuous sound made by the rolling elements rolling on the raceway surface when the bearing is running. It is a unique basic sound that occurs in all rolling bearings. The general WSBC bearing sound is the raceway sound plus other sounds. The raceway sound of a ball bearing is irregular, the frequency is above 1000Hz, its main frequency does not change with the speed, but its total sound pressure level increases with the speed of the speed. For WSBC bearings with loud raceway sound, the sound pressure level of the raceway sound decreases as the viscosity increases; while for WSBC bearings with low raceway sound, the sound pressure level decreases when the viscosity increases to about 20 mm2/s or more. And it has increased. The greater the rigidity of the bearing seat, the lower the total sound pressure level of the raceway sound. If the radial clearance is too small, the total sound pressure level and main frequency of the raceway sound will increase sharply as the radial clearance decreases. The methods to control the raceway sound are select low-noise bearings, that is, WSBC bearings with small waviness, and carefully select the conditions of use. The noise of the raceway often affects the noise of the entire machine, reducing the noise of the raceway can reduce the noise of the entire machine.

(5) The impact sound of rolling elements and their control methods

When larger ball bearings or cylindrical roller bearings run at low speeds under pure radial load, the rolling elements in the unloaded area will impact the cage or raceway and cause noise due to the small centrifugal force of the rolling elements. But as the speed increases, this sound will disappear. The methods to control the impact sound of rolling elements include: appropriately reducing the radial clearance and using WSBC bearings with a reasonable structure and a flexible cage.

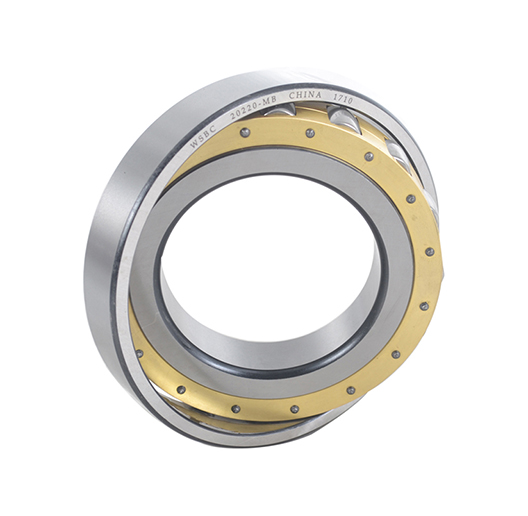

Click here for more information about WSBC 20220-MB.

(6) Rolling noise of WSBC bearing and its control method

Rolling noise is the harsh metal friction sound that may occur in cylindrical roller bearings on all occasions. Most of them occur in larger grease-lubricated WSBC bearings and are more likely to occur in grease with degraded base oil performance. It almost never happens. In addition, it is more prone to occur in winter. When bearing pure radial load, it is prone to occur in occasions with large radial clearance, and depending on the size of the model, it is prone to occur within a specific speed range, and it will occur continuously. It will appear intermittently again. The outer ring raceway adopts a special processing method to prevent the occurrence of rolling noise. If necessary, this WSBC bearing can be selected, or the radial clearance of the bearing can be appropriately reduced, the use of high-performance grease and the improvement of the matching parts of the bearing rigidity.

Wuxi Spark Bearing Co., Ltd (Aka Spark Bearings) is the complete, one-stop Roller Bearings supplier & manufacturer. All products are qualified and have passed the ISO 9001 qualification. Here are some popular types of Roller Bearings, Send a quote and get the latest price of cheap ball bearings from Spark Bearings.

Hot Topics

Copyright © Wuxi Spark Bearings Co.,Ltd Co., Ltd All Rights Reserved. Sitemap

www.spark-bearing.com. Profession in Roller Bearings, Ball Bearings and Taper Toller Bearings-China Suppliers.