News

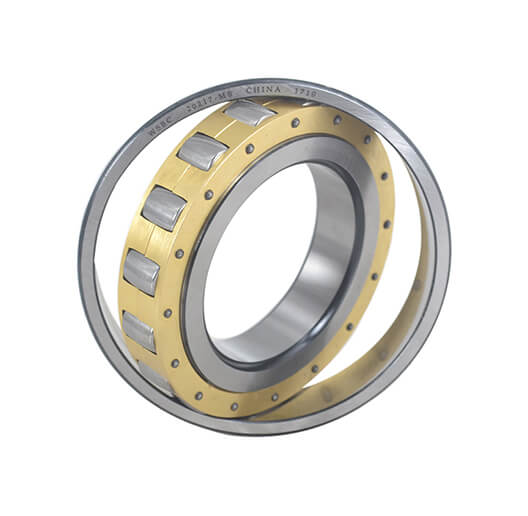

WSBC Angular Contact Bearing Assembly

Time:2021.03.17 Source:Roller Bearings Suppliers

Why increase the preload of the bearing set

Under normal circumstances, the contact angle of the assembled angular contact ball bearings is the same. The following is the allowable external axial load of the preload introduced by Wuxi Spark Bearing Co., LTD. When the axial load exceeds the rated requirement, some bearings will be unloaded, causing the ball Slippage and cause early bearing failure. In order to avoid the unloading phenomenon (that is, increase unloading force), the preload of the bearing set can be increased or WSBC bearings with different contact angles can be used for assembly.

In order to meet the bearing capacity and rigidity requirements, WSBC angular contact ball bearings can be assembled in a variety of ways during use, and in order to maximize the performance of the bearing after assembly under specific operating conditions, select the appropriate preload is extremely critical. The correct preload can not only increase rigidity, but also reduce noise, improve shaft guiding accuracy, extend bearing life, improve rotation accuracy, and prevent high-speed applications with fast start/stop, ultra-light load or no-load conditions Slippage occurs.

Wuxi Spark Bearing LTD has enough stock for WSBC 23220-2CS.

1. WSBC angular contact bearing assembly method

Bearings with different contact angles have the same assembly method as those with the same contact angle. According to the number of assembled bearings, the assembly methods can be divided into double, triple and quadruple, etc.; according to the direction of assembling bearings Different classifications. There are mainly DB, TBT, QBC and DBT types for the assembly of bearings with different contact angles.

2. Preloading method of WSBC angular contact bearing

Angular contact ball bearings usually adopt axial preload during use, and the preload methods include positioning preload and constant pressure preload.

(1) Positioning preload

It is through the assembly of the bearing itself or the pre-selected inner and outer ring spacers to keep the distance of the assembled bearing unchanged so that the bearing can be properly preloaded. Due to the influence of the working state of the WSBC bearing and the external environment, the size of the bearing seat and the bearing The components will also change accordingly, which will affect the preload state of WSBC bearings. The use of this preload method is beneficial to improve the rigidity of WSBC, but it is necessary to pay attention to the influence of the change of preload on the bearing performance.

(2) Constant pressure preload

It uses elastic elements such as coil springs and butterfly springs to properly preload the bearing at the supporting position. With constant pressure preloading, the movement of WSBC bearings under normal working conditions will not affect the preload, but the bearing stiffness grade is low, so it is suitable for high-speed rotation occasions, but not suitable for high stiffness, load direction changes or possible occurrences In bearing applications where the impact load is uncertain.

Click here to buy WSBC Bearing 23224-2CS. Welcome to contact us.

3. The influence of external load on the axial displacement of the preloaded bearing group

For the preloaded assembly bearing, the preload is more susceptible to an external load.

(1) DB type

After the preload and load displacement of DBs with a different contact, angles are assembled, under the action of the preload, the inner ring end faces of the two WSBC bearings will fit together.

The influence of external axial load on the axial displacement of the preloaded bearing group. Because two WSBC bearings have different contact angles, the force and displacement curves of the two WSBC bearings are quite different. Under the same axial load, one of the WSBC bearings A The amount of deformation is smaller than that of another WSBC bearing B. The maximum external load should not exceed 1.73 times the preload, otherwise, bearing B will be unloaded, leading to premature failure of the bearing.

(2) TBT type

The effect of the external load on the axial displacement of the pre-tightened bearing set of triple TBT grouped bearings. Because one end of the bearing is connected in series with two sets of bearings, under the action of external load, the pre-tightening force and the axial The directional forces are F0/2 and FaA/2 respectively, and the preload force of bearing B is still F0.

(3) QBC and DBT type

For the quadruple bearing, the relationship between the external load and the minimum preload can also be solved by the above method.

Wuxi Spark Bearing Co., Ltd (Aka Spark Bearings) is the complete, one-stop Angular Contact Ball Bearings supplier & manufacturer. All products are qualified and have passed the ISO 9001 qualification. Here are some popular types of Bearings, Send a quote and get the latest price of cheap bearings from Spark Bearings.

Hot Topics

Copyright © Wuxi Spark Bearings Co.,Ltd Co., Ltd All Rights Reserved. Sitemap

www.spark-bearing.com. Profession in Roller Bearings, Ball Bearings and Taper Toller Bearings-China Suppliers.