News

Types of Turbocharger Bearings

Time:2020.01.16 Source:Roller Bearings Suppliers

What is a turbocharger?

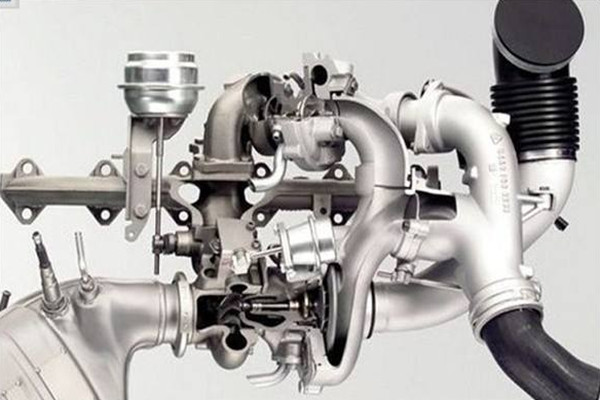

Turbochargers, which are common in automobiles, are an air compressor that increases the amount of air intake by compressing air. It uses the inertia of the exhaust gas from the engine to propel the turbine in the turbine chamber. The turbine drives the coaxial impeller. The impeller pressurizes the air sent from the air filter pipe to pressurize it into the cylinder. When the engine speed increases, the exhaust gas discharge speed, and the turbine speed also increase synchronously, the impeller compresses more air into the bottle, and the rise in air pressure and density can burn more fuel, correspondingly increase the amount of fuel and adjust the engine speed. You can increase the output of the engine.

What are the moving parts of a turbocharger?

The moving parts of the turbocharger are also the most core parts-the turbine impeller, the compressor impeller, and the rotor shaft. There is a high-speed relative movement between the turbocharger housing and the ordinary speed bearing. The bearing of the supercharger is a unique floating bearing.

It is a copper ring that is sleeved on the shaft and the housing. There is a gap between the ring and the shaft and between the ring and the bearing seat. When the engine is operating, under the action of the oil pressure, a double-layer oil film is formed at these parts, and the rotor floats on the oil film to rotate at high speed.

Due to the extremely high speed and high temperature, this part also has exceptionally high requirements for lubrication and cooling.

If the supercharger is not well lubricated and cooled, it will cause abnormal wear of the bearings, significantly shortening the service life of the bearings, the gap between the rotor and the housing will increase, and some oil will enter the intake pipe or exhaust pipe from this part. , Resulting in severe burn-in oil failure.

Type of turbocharger bearings

As a critical moving part of a turbocharger, its structure is related to the reliability and durability of the turbine. Turbocharger bearings are mainly divided into two categories, one is floating bearings (commonly known as Boss bearings), and the other is ball bearings.

Most major auto manufacturers now use floating bearings, which should be durable and affordable. The floating bearing is a ring on the shaft. There is a gap between the ring and the shaft and between the ring and the bearing seat, forming a double-layered oil film. The ring floats between the shaft and the bearing housing. Generally, the inner layer gap is about 0.05mm, and the outer layer gap is about 0.1mm. The wall thickness of the bearing is about 3.0-4.5mm, and it is made of tin-lead bronze alloy. The surface of the bearing is plated with a layer of lead-tin alloy or metal indium with a thickness of about 0.005-0.008mm. When the supercharger works, the bearing rotates between the shaft and the bearing housing. Therefore, we can find the disadvantages of floating bearings: the turbine shaft has high running resistance at high speeds, high oil pressure and quality requirements, and unstable dynamic control of the turbine shaft.

Ball bearings can be seen more on performance models. Ball bearings are balls mounted on turbine shafts to replace the position of the oil in floating bearings. The advantage of the ball bearing is precisely the opposite of the floating bearing: the friction is smaller, the effect of the turbine hysteresis is lower, and the compression of the power limit is more favorable; the dynamics of the turbine shaft can be effectively controlled; the oil pressure and quality can be slightly reduced, Which indirectly increases the life of the turbine. Its shortcomings are also apparent, that is, the experience is not as good as that of floating bearings. Generally, the life limit is reached from 70,000 to 80,000 kilometers, and the maintenance cost is expensive and difficult to maintain. However, because ball bearings are extremely attractive in terms of increasing power, ball bearings are still mainstream equipment on performance models.

Hot Topics

Copyright © Wuxi Spark Bearings Co.,Ltd Co., Ltd All Rights Reserved. Sitemap

www.spark-bearing.com. Profession in Roller Bearings, Ball Bearings and Taper Toller Bearings-China Suppliers.