News

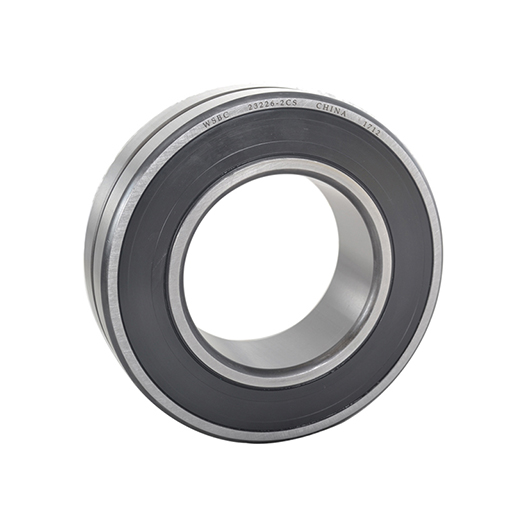

The Use And Testing Of WSBC Bearings

Time:2020.09.23 Source:Roller Bearings Suppliers

The use factors of WSBC imported bearings mainly refer to whether the installation adjustment, use and maintenance, maintenance and repair meet the technical requirements. According to the technical requirements of WSBC imported bearing installation, use, maintenance and maintenance, the load, speed, working temperature, vibration, noise and lubrication conditions of the bearing in operation are monitored and checked. If an abnormality is found, the cause will be immediately found and adjusted. Bring it back to normal. Installation conditions are one of the most important factors in the use of factors. WSBC imported bearings are often due to improper installation, resulting in changes in the stress state between the parts of the entire set of bearings. WSBC imported bearings run under abnormal conditions and end their service life early. The internal factors mainly refer to the three major factors that determine the quality of WSBC imported bearings, such as structural design, manufacturing technology and material quality.

1) WSBC imported bearing design parameters: including the number of bearing rolling elements, ring wall thickness and clearance, etc.

2) Manufacturing error of WSBC imported bearing parts: including the surface roughness, cross pattern and roundness difference of WSBC imported bearing raceway and rolling element. A large number of experimental studies have shown that the influence of waviness on bearing vibration is dominant, while the influence of surface roughness and roundness is relatively small.

3) Working conditions of imported WSBC bearings: During the operation of the bearing, load, speed and lubrication conditions have the greatest impact on the vibration of imported WSBC bearings.

4) WSBC imported bearing installation parameters: the fit between the bearing and the shaft and the bearing seat, the deviation during installation and other factors also affect the vibration of the WSBC imported bearing. Wuxi Spark Bearing Co.,Ltd provides WSBC 23226-2CS online, contact us for more information about it.

WSBC bearings are the main components of locomotives, especially the traction motor and axle box WSBC bearings. Their functions play a decisive role in safe transportation. When the locomotive is running on the line, once the WSBC bearing fails, the entire train will not run and the transportation will be blocked. The failure of the main line, especially the passenger train, will have a greater negative impact. At the same time, once the locomotive bearing fails, it is very difficult to repair the locomotive. Therefore, preventing and reducing the occurrence of the WSBC locomotive bearing failure is important for the safe transportation of the locomotive. It is very important. It is the focus of this article that whether the WSBC bearings with potential faults can be detected before the WSBC bearings are installed, and to ensure that the qualified WSBC bearing parts are on the car.

Severe damage to WSBC bearings is often not caused by a single cause, but a vicious circle is generated under severe operating conditions under the combined effects of several aspects, which leads to severe burns of WSBC bearings. Therefore, it is often difficult to judge after an accident. What is the reason is that it brings some difficulties for us to formulate relevant measures. For the convenience of discussion, first analyze the causes of WSBC bearing failure from several aspects.

When the WSBC bearing is used for a period of time, certain defects and scars will occur in the inner ring, body, cage, outer ring, raceway, etc. of the bearing, resulting in poor lubrication of the WSBC bearing, and heating of the WSBC bearing. : (1) Dilution of WSBC bearing lubricant. (2) Accelerate the fatigue of the material and decrease the hardness. Due to the above reasons, a vicious circle is further formed, accelerating overheating and burning WSBC bearings. Severe WSBC bearing inner ring displacement, body out of round, collision and heat generation, and finally welded together. Therefore, when running on the line, if you find that the WSBC bearing is seriously hot or smoking, do not stop, but keep running to the front station, because at this moment the overheated WSBC bearing is in a molten state, and once it is stopped and cooled, it can no longer walk and block the main line. WSBC 23228-2CS online, click here for more details.

It is very important for the oil maintenance of the WSBC bearings of the locomotive, especially the proper amount of lubrication to the bearings can ensure that the bearings have good lubrication. Lack of oil and too much oil can easily cause WSBC bearing failure, and less oil can easily cause bearing lubrication. If it is bad and heat, it will easily cause overheating when adding too much. Therefore, the oil should be properly supplied during maintenance. At the same time, the cleaning of the lubricating grease of WSBC bearings is also very important. Once the grease falls into other impurities and moisture, it will affect the normal swimming And establish the necessary oil film.

The service life of WSBC bearings is too long, exceeding the service life of WSBC bearings, and it is easy to cause material fatigue. Coupled with strong impact, the material is deformed, causing the rollers and raceway surfaces to peel off and grind, resulting in poor lubrication and Vibration increases.

WSBC bearing inner ring and shaft fit clearance interference does not match, it is also easy to cause WSBC bearing failure, large interference, it is easy to cause WSBC bearing inner ring to crack due to excessive tensile stress, too small interference, but also It is easy to cause "slack" in the inner ring of WSBC bearings.

Improper clearance fit of WSBC bearing assembly may also cause bearing failure. Small clearance can easily cause friction and heating of rollers and raceways. As the temperature continues to rise, the inner ring, body, cage, outer ring, and end of WSBC bearing The temperature of the cover is not the same, there is a temperature difference between each other, so the amount of expansion is also slightly different, which leads to a further reduction in the fit gap, plus the heat generation of WSBC bearings. If the clearance is too large, the vibration of the roller will increase, which will aggravate the impact of the roller and the raceway. At the same time, it will also easily cause uneven internal load distribution, reduce the load-bearing roller, and excessive load on the central roller.

When assembling the bearing, the WSBC bearing was impacted with a copper hammer, causing deformation of the cage, incorrect installation of the inner and outer rings of the traction motor bearing, or other reasons, which caused the axial lateral momentum to disappear, causing the WSBC bearing shaft to squeeze.

Hot Topics

Copyright © Wuxi Spark Bearings Co.,Ltd Co., Ltd All Rights Reserved. Sitemap

www.spark-bearing.com. Profession in Roller Bearings, Ball Bearings and Taper Toller Bearings-China Suppliers.