News

Standard for Cylindrical Roller Bearings

Time:2020.05.21 Source:Roller Bearings Suppliers

Bearing is an important part of modern machinery and equipment.Its main function is to support the mechanical rotating body, reduce its friction coefficient in the process of motion, and ensure its rotation accuracy.

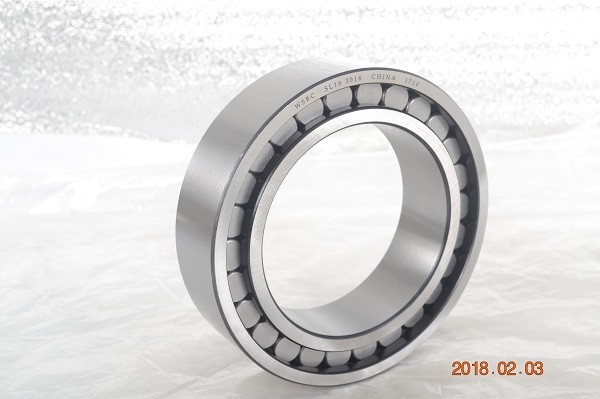

According to the different frictional properties of moving elements, bearings can be divided into rolling bearings and sliding bearings.Among them, the rolling bearing has been standardized and serialized, but compared with the sliding bearing, its radial size, vibration and noise are larger, and the price is higher.Need WSBC SL183016,click here to learn more

Bearing clearance

The clearance of the bearing refers to the amount of movement of the other ring from one limit position to another limit position relative to the fixed ring when there is no load when one ring is stationary.Radial movers are called radial clearance, and axial movers are called axial clearance.The clearance of the bearing is an important technical parameter for the normal operation of the bearing, which directly affects the load distribution, friction, temperature rise and service life of the bearing.In the selection of clearance should be based on the rolling load, the type of rolling mill, rolling precision, speed,lubrication, temperature rise and fit interference and other specific conditions to consider.For clearance of various bearings, please refer to the foregoing part of the dimension and performance table of various bearings.Among them, radial clearance is given by four-row cylindrical roller bearings, double-row cylindrical roller bearings and deep-groove ball bearings: axial clearance is given by double-row angular contact ball bearings, two-way thrust tapered roller bearings, four-point contact ball bearings and single-row angular contact ball bearings mounted in pairs.

Limit speed

The rotational speed of the rolling bearing is mainly limited by the temperature rise caused by the friction and heating inside the bearing. When the rotational speed exceeds a certain threshold value, the bearing will become sticky due to the increasing temperature, so that it cannot be used.

The limit speed of the bearing is the limit value of the bearing speed when the bearing reaches the maximum thermal equilibrium temperature under certain working conditions.It is related to bearing type, structure size, load size, lubricant and lubrication mode, bearing tolerance class, clearance, cage structure and material, cooling conditions and other factors.The limit speed listed in this sample is: inner rotation;The radial load is only borne by the centripetal bearing and the axial load is only borne by the thrust bearing.

Q&A

It is impossible to directly observe the bearing during operation, but the abnormal bearing can be detected by the noise, vibration, temperature, lubricant and other conditions.

Installation and maintenance

Installation of rolling mill bearings

The service life of rolling mill bearing is not only related to the quality of bearing, but also to its installation and use.Therefore, we should attach importance to the technical requirements of bearing installation and observe the relevant operating procedures.

Preparation before installation

(1) before installation, all fitting parts, including the matching surface of roller neck, bearing box, bearing ring and bearing box cover plate, shall be carefully checked to check whether their size, shape, position accuracy and matching tolerance meet the technical requirements of the design.

(2) on the surface matched with the bearing, the edges and burrs of the roller neck, bearing box hole and oil hole must be removed, cleaned and coated with lubricating oil.

Remove

(1) the order of disassembly is opposite to that of installation.First remove the axle box from the roller and place it upside down

(2) remove the front end cover and lift the outer ring component with appropriate tools

(3) hoist the upper outer ring component to the oil hole of the outer component and align it with the end face of the axle box, and the oil hole can be seen from the side of the axle box

(4) after inserting the pin shaft into the three oil holes, fix the outer ring assembly

(5) push down the lower outer ring component

(6) first lift out the upper outer ring component, and then lift out the lower outer ring component

(7) be careful not to mix the removed bearing with other parts, and also note that the side screw holes of the cage cannot be used as external components for lifting (available for installation).

Inspection and maintenance

Due to high load operation, in order to reduce the damage caused by bearing fatigue or lubrication failure, the inspection and maintenance cycle is generally 3 to 6 months.

All oxide rust and other dirt shall be removed from the outside of the axle box before the bearing is removed from the axle box.The unloaded bearings are to be cleaned.The cleaned bearings should be visually inspected first.Need WSBC LSL192334-TB,click here

The operating end is the double inner ring double row angular contact ball bearing, which is used as the rolling roller axial positioning bearing, and the deep groove ball bearing is used as the axle box positioning bearing. The outer ring need not be clamped too tightly.The double inner ring double row angular contact ball bearings are fitted to the sleeve with interference fit, while the sleeve itself is fitted to the rollers with clearance fit.Usually lubricated with grease, high - speed oil mist lubrication or oil - gas lubrication.Usually double inner ring double row angular contact ball bearings can also be replaced by four-point contact ball bearings, can save space position.

Hot Topics

Copyright © Wuxi Spark Bearings Co.,Ltd Co., Ltd All Rights Reserved. Sitemap

www.spark-bearing.com. Profession in Roller Bearings, Ball Bearings and Taper Toller Bearings-China Suppliers.