News

Maintenance Of WSBC Bearings

Time:2020.12.30 Source:Roller Bearings Suppliers

In order to maintain the original performance of the bearing in a good condition for as long as possible, maintenance, inspection and repair are necessary to prevent accidents before they occur, ensure the reliability of operation, and improve productivity and economy. Maintenance should be carried out regularly in accordance with the operating standards of the mechanical operating conditions. The contents include monitoring the operating status, replenishing or replacing lubricants, and regular disassembly inspections. As for maintenance items during operation, there are bearing rotation noise, vibration, temperature, lubricant state, etc. Therefore, the maintenance, overhaul, and abnormal handling of bearings are playing an important role in the life of WSBC bearings.

Damage and countermeasures of WSBC bearing

Generally, if the bearing is used correctly, it can be used until the fatigue life is reached. But there may be accidental premature damage and intolerance to use. This early damage, as opposed to fatigue life, limits the use of qualities called failures or accidents. It is mostly caused by careless installation, use, and lubrication, foreign matter invaded from the outside, and insufficient research on the thermal effect of the shaft and housing.

Regarding the damage state of the WSBC bearing, such as the jam of the ring rib of the roller bearing, the reasons can be considered, insufficient lubricant, unsuitability, defects in the oil supply and drainage structure, foreign matter intrusion, bearing installation errors, and shaft deflection. If the song is too big, these reasons will overlap.

Therefore, it is difficult to know the real cause of the damage only by investigating the damage of the WSBC bearing. However, if you know the machinery of the bearing, the operating conditions, the structure around the bearing, and the situation before and after the accident, combined with the damaged state of the bearing and several reasons, you can prevent similar accidents from happening again.

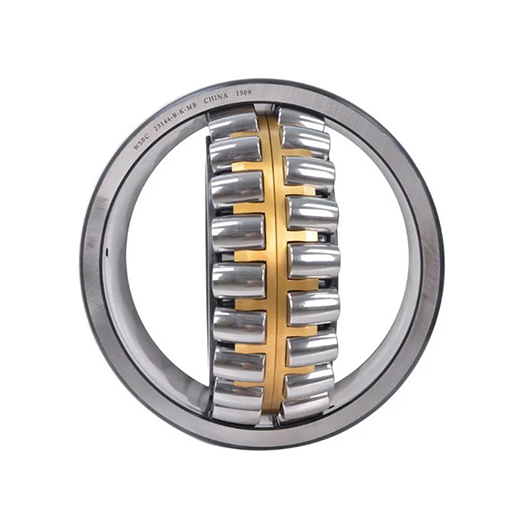

Wuxi Spark Bearing Co., Ltd provides WSBC 23144-B-K-MB, click here for more details.

The precautions for the use of WSBC bearings are as follows

Keep WSBC bearings and their turnover clean

Even small dust invisible to the eyes will have a bad effect on WSBC bearings. Therefore, keep the surroundings clean to prevent dust from entering the WSBC bearing.

Use with caution

A strong impact on the WSBC bearing during use will cause scars and indentations, which will cause accidents. In severe cases, it will crack or break, so be careful.

Use appropriate WSBC operating tools

Avoid replacing existing tools and tools, and must use appropriate tools. We often emphasize the importance of tools because too many customers have used the wrong tools in the installation and caused damage to WSBC bearings.

Pay attention to the corrosion of WSBC bearings

When handling WSBC bearings, sweat on your hands can cause rust. Pay attention to the operation with clean hands, it is best to wear gloves.

Contact us to buy WSBC SL045005-PP. We have enough stock.

Vibration can be said to be quite sensitive to the damage of WSBC bearings, peeling, indentation, corrosion, cracks, wear, etc. will be reflected in the vibration measurement of WSBC bearings. Therefore, by using a special WSBC bearing vibration measuring device (frequency analyzer, etc.), the magnitude of the vibration can be measured, and the specific abnormal situation cannot be inferred through the frequency division. The measured value varies with the use conditions of the WSBC bearing or the installation position of the sensor, so it is necessary to analyze and compare the measured value of each machine in advance to determine the judgment standard.

The effect of temperature on WSBC bearings

Let's take a look at the effect of temperature on the bearing. The high temperature often indicates that the WSBC bearing is in an abnormal condition. High temperature is also harmful to the lubricant of WSBC bearings. Sometimes bearing overheating can be attributed to the lubricant of WSBC bearings. Long-term continuous rotation of bearings at temperatures exceeding 125°C will reduce the life of WSBC bearings. Causes of high-temperature bearings include insufficient or excessive lubrication, lubricants. Containing impurities, excessive load, WSBC bearing ring damage, insufficient clearance, and high friction caused by oil seals, etc.

Therefore, it is necessary to continuously monitor the temperature of WSBC bearings, whether it is to measure the bearing itself or other important parts. If the operating conditions remain unchanged, any temperature change can indicate that a malfunction has occurred. WSBC bearing temperature can be measured regularly with the help of a thermometer, such as WSBC digital thermometer, which can accurately measure the WSBC bearing temperature and display it in ℃ or Fahrenheit. The important bearing means that when it is damaged, it will cause the shutdown of the equipment, so it is better to install a temperature detector for this type of WSBC bearing.

Wuxi Spark Bearing Co., Ltd (Aka Spark Bearings) is the complete, one-stop Sealed double row full complement cylindrical roller bearings supplier & manufacturer. All products are qualified and have passed the ISO 9001 qualification. Here are some popular types of Sealed double row full complement cylindrical roller bearings, Send a quote and get the latest price of cheap ball bearings from Spark Bearings.

Hot Topics

Copyright © Wuxi Spark Bearings Co.,Ltd Co., Ltd All Rights Reserved. Sitemap

www.spark-bearing.com. Profession in Roller Bearings, Ball Bearings and Taper Toller Bearings-China Suppliers.