News

Elimination of Common Faults of Needle Roller Bearings

Time:2020.07.03 Source:Roller Bearings Suppliers

Needle roller bearings are roller bearings with cylindrical rollers, which are commonly seen in automobiles or motorcycles in our daily life. Needle roller bearings cannot avoid some failures when they are used. Wuxi Spark Bearing Co., Ltd According to the understanding of needle roller bearings, tell you about some common fault factors of needle roller bearings and related methods to eliminate bearing faults.

Common faults and causes of needle roller bearings:

1. Failure form:

(1) Difficult bearing rotation and heat generation;

(2) There is abnormal noise in bearing operation;

(3) Bearing vibration;

(4) Peeling and cracking of the inner seat ring;

(5) Peeling and cracking of the outer seat ring;

(6) The bearing raceways and rolling elements produce indentation.

2. Analysis of failure cause:

(1) Inadequate inspection before assembly

The bearings must be cleaned and carefully inspected before and after the assembly of the bearing inner and outer races, rolling elements and cages, whether there are rust, burrs, bruises and cracks; check the bearing clearance is appropriate. Whether the rotation is light and free, whether there is a sudden lock At the same time, check the shaft diameter and the size, roundness and cylindricity of the bearing seat hole and whether there are burrs or unevenness on the surface. For split bearing housings, a gap of 0.1mm to 0.25mm should be left between the joint surface of the bearing cap and the bearing base and the outer circular surface of the outer seat ring to prevent "clamps" from appearing on the "tiles" on both sides of the outer seat The gap caused by the "help" phenomenon is reduced and the wear is accelerated, causing premature bearing damage.

(2) Improper assembly

Improper assembly will cause the above-mentioned various failure forms of the bearing, as well as the following situations:

a. Improper cooperation:

The base hole is used for the cooperation between the bearing inner hole and the shaft, and the base shaft is used for the cooperation between the bearing outer circle and the bearing seat hole. The shafts and bearing inner races of centrifugal pumps, centrifuges, reducers, motors and centrifugal compressors that generally work under normal load conditions use J5, js5, js6, k5, k6, and m6 to cooperate, and the bearing seat holes and bearings The outer seat ring adopts j6 and J7. Rotating seat ring (the inner seat ring of most bearings is a rotating seat ring, the outer seat ring is not a rotating seat ring, and the opposite is true for a small number of bearings), usually an interference fit is used to avoid the seat ring in the shaft diameter under load. Rolling and sliding occur on the mating surface of the housing bore.

But sometimes due to the inaccurate measurement of the shaft diameter and the bearing seat hole size or the mating surface roughness does not meet the standard requirements, resulting in an excessive interference fit, the bearing seat ring is greatly squeezed, resulting in the radial clearance of the bearing itself The reduction will make the bearing difficult to rotate, generate heat, increase in wear or be stuck, and in serious cases will cause the inner and outer bearing rings to crack when installed. The non-rotating seat ring often adopts the clearance or the interference with little interference, so that the non-rotating seat ring may produce slight creep, and the contact surface of the seat ring and the rolling body is continuously replaced, and the raceway raceway wears evenly. At the same time, the phenomenon of axial seizure of the rolling elements in the bearing due to thermal elongation can also be eliminated. However, the excessive clearance fit will cause the non-rotating seat ring to rotate with the rolling body, resulting in serious wear on the shaft (or bearing seat hole) and the inner seat ring (or outer seat ring), and friction will cause the bearing to heat and vibrate.

b. Improper assembly method:

When the interference between the bearing and the shaft diameter or the bearing seat hole is small, the press-in method is often used for assembly. The easiest way is to use copper rods and hand hammers to strike the bearing ring with interference fit symmetrically in a certain order, so that the bearing is smoothly pressed in. In addition, a soft metal casing can also be driven in with a hammer or pressed in with a press. Improper operation will cause the seat ring to be deformed and cracked, or the hand hammer will hit the non-interference fit seat ring, which will cause indentation of the raceway and rolling element or the bearing will be damaged indirectly.

c. Improper temperature control during assembly:

When the needle roller bearing is assembled, if it has a large interference with the shaft diameter, it is generally assembled by hot assembly. Put the bearing in the oil barrel containing organic oil, and the outside of the oil barrel is heated with hot water or flame. The process requires the temperature of the heated oil to be controlled at 80 ℃ ~ 90 ℃, generally not exceeding 100 ℃, at most not exceeding 120 ℃. After the bearing is heated, it is quickly taken out and put on the journal. If the heating temperature is too high due to improper temperature control, the bearing will be tempered and the hardness will be reduced. During operation, the bearing will be easily worn, peeled, or even cracked.

d. Improperly found coupling:

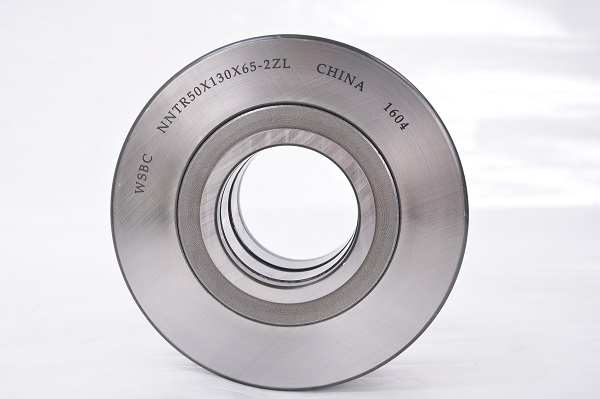

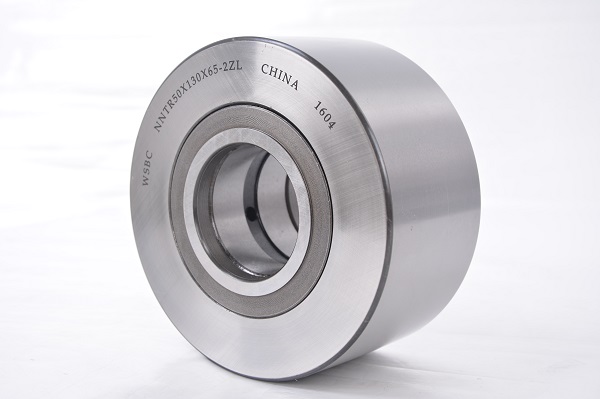

The input shaft of most running equipment is connected to the power shaft through a coupling, so the coupling must be aligned during assembly so that the driving shaft and the driven shaft are on the same axis. Need WSBC NNTR50X130X65-2ZL 22236CCK/W33, click here to learn more.

(3) Poor lubrication

The lubricating oil (or grease) used in needle roller bearings has a certain working temperature. When the temperature is too high, it will deteriorate and lose its lubricating effect, causing the bearing to be damaged due to high temperature. In addition, the lubricating oil (or lubricating grease) itself is poor in texture or the lubricating (grease) is not timely in operation, which will also cause the bearing temperature to rise or produce abnormal noise.

(4) Rotor unbalance

In general, the rotor of the running equipment must be balanced dynamically and statically before assembly, so the bearing will not have problems. However, due to the corrosion of the medium or the wear of solid impurities or the bending of the shaft during operation of the rotor, unbalanced centrifugal force will be generated, which will cause the bearing to heat, vibrate, and the raceway will wear seriously until it is destroyed.

(5) Check and replace in time

During the operation of the bearing, check regularly according to the regulations. If there is heat, abnormal noise, vibration, etc., stop in time to find the cause and eliminate the fault. If the bearing finds serious fatigue peeling, oxidation rust, worn pits, cracks, hardness When it is reduced to HRC<60, or there is too much noise to adjust, it should be replaced in time. If the inspection and replacement are not timely, it will cause serious damage to the bearing and even the rotor, thus affecting normal production. In addition, vibrations caused by improper bearing disassembly and loose bolts of the equipment can also cause indentation of the bearing raceways and rolling elements, and cracks in the inner and outer races of the bearings.

Methods to eliminate needle roller bearing failure:

(1) When replacing the bearing, the new bearing should be carefully inspected, and the shaft diameter, bearing seat hole and rotor should be carefully inspected;

(2) When assembling and disassembling the bearing, strictly implement the maintenance process and operate carefully to avoid bearing damage caused by improper assembly and disassembly;

(3) Add oil and change oil on time to ensure that the working condition of the bearing is always in good condition;

(4) Check carefully during operation, find hidden troubles and eliminate them in time.

Hot Topics

Copyright © Wuxi Spark Bearings Co.,Ltd Co., Ltd All Rights Reserved. Sitemap

www.spark-bearing.com. Profession in Roller Bearings, Ball Bearings and Taper Toller Bearings-China Suppliers.