News

Do you know the function and usage Do you know the functions and USES of tapered roller bearings?

Time:2020.02.28 Source:Roller Bearings Suppliers

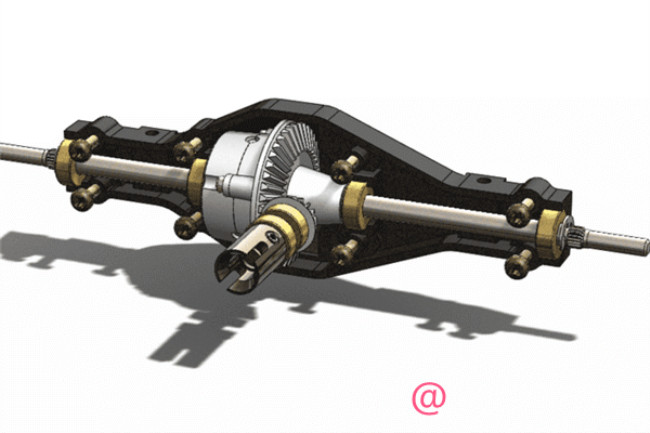

Cone roller bearings have inner cone ring and outer ring raceway, cone roller arranged between the two. All projection lines on the surface of the cone meet at the same point on the bearing axis. This design makes tapered roller bearings especially suitable for bearing compound (radial and axial) loads. The contact Angle mostly determines the axial load capacity of the bearing; The more significant the Angle, the higher the axial load capacity. The calculated coefficient e expresses the Angle; The higher the value of e, the greater the contact Angle, the higher the bearing's suitability to bear axial load.

Tapered roller bearings are usually separable, that is, the conical inner ring assembly consisting of the inner ring with the roller and cage assembly can be installed separately from the tapered outer ring (outer ring).

Cone roller bearings are widely used in automobile, rolling mill, mining, metallurgy, plastic machinery, and other industries.

The secondary reason for the emergence of scars in the installation process of a tapered roller bearing is that the inner ring and the outer ring are out of alignment when the bearing is being installed and assembled. Or perhaps it is the emergence of charging loads in the process of installation and assembly, resulting in bearing emergence scars.

Conical roller bearings are installed by the work specifications to stop, will not form a lot of results, such as the form of the device or method is not appropriate, will form the raceway surface of the bearing and the grinding surface of the linear bearing scars emerge. The apparatus of deep groove ball bearing indirectly reflects the precision, life, and function of the bearing in use.

Although the quality of tapered roller bearing and other aspects are relatively sound, the rolling bearing is a precision part; its use should be correspondingly cautious.No matter how high-performance bearings are used, if not handled properly, the desired high performance will not be achieved. There are the following matters needing attention in the use of bearings:

(1) keep the tapered roller bearing and its surroundings clean.

Even if the eyes can not see the small dust, it also can bring an adverse effect on the bearing. Therefore, to keep the surrounding clean, so that dust will not invade the bearing.

(2) use with caution.

In use to give cone roller bearings strong impact, will produce scars and indentation, become the cause of the accident. In severe cases, cracks and fractures will occur, so attention must be paid.

(3) use appropriate operating tools.

Avoid replacing existing tools with appropriate ones.

(4) pay attention to the cone roller bearing corrosion.

When handling bearings, sweat on the hands can become a cause of rust. Use clean hands and wear gloves.

Tapered roller bearings use hearing to identify irregular movements, such as electronic stethoscopes, to detect abnormal noise from a part used by experienced operators. If the bearing is in good working condition, it will give out a low whine sound. If it gives out a sharp hiss sound, cone roller bearing, squeak, and another irregular sound, it usually indicates that the bearing is in bad working condition.

1. Tile surface corrosion: abnormal concentration of nonferrous metals was found by spectral analysis; There are many submicron wear particles of nonferrous metal components in demography. Lubricating oil moisture exceeds bid; acid value exceeds the bid.

2. Journal surface strain: There are iron cutting abrasive particles or black oxide particles in the iron spectrometer, and the metal surface has been re-ignited.

3. Surface corrosion of the journal: abnormal concentration of iron was found by spectral analysis. Submicron particles containing many iron components were found in the iron spectrum.

4. Surface strain: Machining abrasive grains are located in the iron spectrometer. These abrasive grains are composed of nonferrous metals.

5. Fretting wear on the back of the tile: abnormal iron concentration was found by spectral analysis. There were many iron submicron wear particles in the iron spectrum, and excellent water content and an acid value of lubricating oil.

Under the condition of liquid lubrication, the sliding surface is separated by lubricating oil without direct contact, and the friction loss and surface wear can be significantly reduced.

The squeaky noise may be caused by improper lubrication. Improper bearing clearance can also cause metallic noise. The indentation on the outer ring track of the cone roller bearing will cause vibration and give rise to smooth and clear sound. If the tapping scar causes it during installation, the noise will be different from the speed of the bearing. If there is intermittent noise, it indicates that the roller may be damaged. The sound of cone roller bearing occurs when the damaged surface is rolled out. If there are pollutants in the bearing, they often cause hiss.

Hot Topics

Copyright © Wuxi Spark Bearings Co.,Ltd Co., Ltd All Rights Reserved. Sitemap

www.spark-bearing.com. Profession in Roller Bearings, Ball Bearings and Taper Toller Bearings-China Suppliers.