News

Anti-rust Inspection Work For Spherical Roller Bearings

Time:2020.05.11 Source:Roller Bearings Suppliers

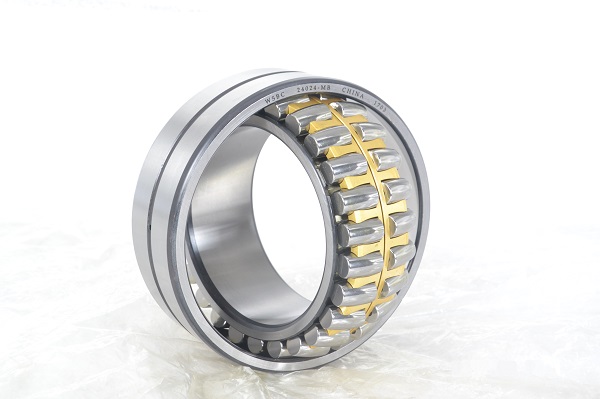

Spherical roller bearings have two rows of rollers, which mainly bear radial loads and can also withstand axial loads in either direction. With high radial load capacity, it is especially suitable for work under heavy load or vibration load, but can not bear pure axial load. The raceway of the outer ring of this type of bearing is spherical, so its self-aligning performance is good, and it can compensate the coaxiality error.

There are two rows of symmetrical spherical rollers. The outer ring has a common spherical raceway. The inner ring has two raceways inclined at an angle to the bearing axis. It has good self-aligning performance. When the shaft is bent or installed out of center The bearing can still be used normally. The self-alignment varies with the bearing size series. Generally, the allowable self-aligning angle is 1 ~ 2.5 degrees. The load capacity of this type of bearing is large. In addition to the radial load, the bearing can also withstand. Axial loads acting in both directions have better impact resistance. Generally speaking, the working speed allowed for spherical roller bearings is lower. Bearings WSBC 23232CCK/W33 online , pls click here :

In the application process of bearings, if corrosion occurs, it will have a very adverse effect on the industry, so it is necessary to strengthen the anti-rust measures for spherical roller bearings. There are two main aspects in bearing anti-rust, one is anti-rust treatment in process, and the other is anti-rust treatment in finished product.

Management of antirust technology for spherical roller bearings

In order to ensure that the anti-rust process can be carried out seriously, the technical department formulates specific evaluation rules according to the process requirements, and converts the composition value to evaluate the production plant. The first-level anti-rust management personnel conduct monthly process discipline inspection on the production plant. The management of cooling water, anti-rust liquid, cleaning fluid, anti-rust oil and the rust rate, cleanliness and oiled packaging of the finished bearing are The management level of the rust staff and the monitoring situation of the monitoring project are subject to a comprehensive inspection, assessment and scoring, and the assessment results are issued to the production plant. A regular meeting of rust prevention personnel is held once a month to summarize the company's monthly inspections and problems, and to propose improvement measures to rectify within a time limit; at the same time, it also provides opportunities for rust prevention personnel to communicate and learn from each other. Establish a rust management work network, so that the rust prevention work has a good management foundation.

Management of anti-rust auxiliary materials for spherical roller bearings

The quality of the anti-rust material for spherical roller bearings directly affects the quality of product processing. Therefore, when selecting anti-rust materials, first conduct physical and chemical performance testing according to the quality requirements, and then conduct a pilot test after passing the test. . The selected anti-rust auxiliary materials will be strictly tested according to the quality standards of different materials after entering the factory. During the use process, the anti-rust material and the prepared solution shall be tested regularly to ensure that the concentration and proportion of the solution meet the technological requirements and reach the performance. The establishment of a complete material acceptance system and quality acceptance standards provides a reliable guarantee for good anti-rust management.

Spherical roller bearings are coated with anti-rust oil and sealed to avoid the influence of atmospheric environment during storage and transportation, which may cause rust and mildew and affect the performance.

The finished spherical roller bearings are washed twice by kerosene mechanical spraying, mechanical spraying anti-rust and lubricating dual-use oil, and polyethylene sealed packaging.

Before kerosene spraying and anti-rust lubricating dual-use oil spraying, use filter elements that meet the process requirements to ensure the cleanliness of the finished spherical roller bearings. The oil tank and machine tool are thoroughly cleaned once a month. When inspectors and assembly personnel touch the finished parts and bearings, liquid gloves should be applied to avoid corrosion due to hand sweat. Handle and store the finished spherical roller bearings during storage to avoid damage to the packaging. The assembly room and finished bearing storage room should be dry, clean and free of pollution sources.

The inspection of spherical roller bearings mainly includes the following points

Quality of spherical roller bearings

During the disassembly of the bearing box, first of all, check whether the grease has bad conditions such as deterioration, agglomeration, and impurities, which is an important basis for judging the cause of bearing damage. Secondly, check the bearings for bite and wear; check the surface finish of the bearing inner and outer rings, rolling elements, cages and for defects such as cracks, rust, peeling, pits, overheating and discoloration, and measure whether the bearing clearance exceeds the standard; check If the bushing is worn, pitted or peeled, new bearings should be replaced if above.

Fitting of spherical roller bearings

When the bearing is installed, it is very important to match the inner diameter of the bearing with the shaft, the outer diameter and the housing. When the fit is too loose, the mating surface will produce relative sliding called creep. Once the creep occurs, it will wear the mating surface and damage the shaft or casing, and the wear powder will invade the inside of the bearing, causing heat, vibration and destruction. When the interference is too large, the outer diameter of the outer ring will become smaller or the inner diameter of the inner ring will become larger, reducing the internal clearance of the bearing. In order to select the fit for the application, various factors such as the nature, size, temperature conditions of the bearing load, and the rotation of the inner and outer rings must be considered.

Adjustment of Fitting Clearance of Spherical Roller Bearing

If the clearance of the spherical roller bearing is too small, the frictional loss of grease in the clearance will be too large, which will also cause the bearing to heat up. At the same time, if the clearance is too small, the amount of oil will be reduced, and the heat generated by the friction will not be taken away. The temperature rise of the bearing. However, if the gap is too large, it will change the dynamic characteristics of the bearing, causing unstable rotor operation. Therefore, it is necessary to select the verified bearing clearance for different equipment and use conditions.

Hot Topics

Copyright © Wuxi Spark Bearings Co.,Ltd Co., Ltd All Rights Reserved. Sitemap

www.spark-bearing.com. Profession in Roller Bearings, Ball Bearings and Taper Toller Bearings-China Suppliers.