News

Installation and Common Problems of Bearing Pedestal

Time:2020.01.09 Source:Roller Bearings Suppliers

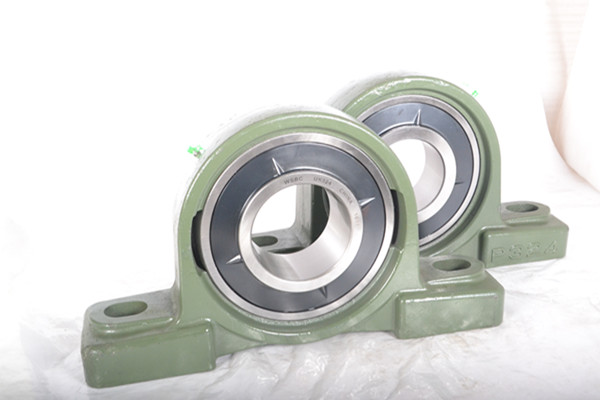

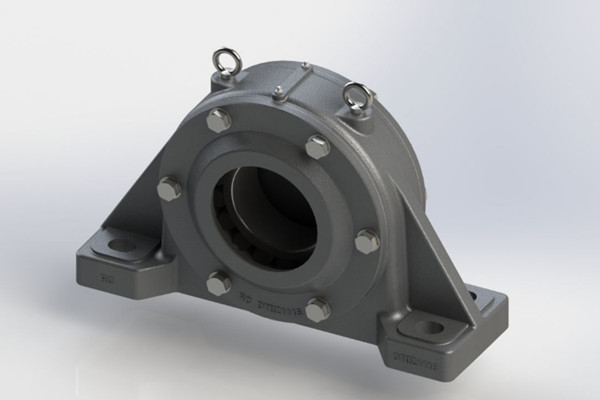

Because a bearing can use different bearing housings, and a bearing housing can also use different types of bearings at the same time, there are many types of bearing housings. For various applications of standard bearing housings, bearing housings of different materials can be selected, such as special cast iron housings of gray cast iron, ductile iron, and cast steel, stainless steel, and plastic.

According to the different requirements of bearings and bearing housings, the classification of bearing housings is not precisely the same. When using them, they must be carefully checked and selected according to the design.

The role of the bearing pedestal As a close partner of the bearing, the bearing pedestal plays an essential role in the entire shafting. It is generally located at both ends of the shaft, and its primary function is to support and fix the bearing so that the shaft and its connecting parts have a specific positional relationship. Besides, the bearing housing is generally provided with a sealing device, thereby reducing the pollution of the bearing.

Bearing pedestal installation method

(1) Press-fit method

You can press the bearing on the shaft first with a press, and then install the shaft and the bearing into the bearing housing hole. When pressing, pay attention to the end face of the inner ring of the bearing, and pad a fitting made of soft metal material. Tube, and the inner diameter of the mounting sleeve should be larger than the width of the journal, and the outer diameter should be smaller than the inner ring flange of the bearing. The outer ring of the bearing should fit tightly with the bearing housing hole. If the inner circle and the shaft fit loosely, the bearing can be pressed into the bearing housing hole first. At this time, the outer diameter of the mounting sleeve should be smaller than the width of the housing hole. If the bearing ring fits tightly with the shaft and seat hole, press the inner and outer rings into the cylinder and seat hole at the same time.

(2) Heating method

This is a standard and labor-saving installation method. It uses thermal expansion to change the tight fit into a loose fit. First, put the bearing or separable bearing ring into the oil tank for uniform heating. The temperature range is generally 80-100 ° C. After baking, remove it from the oil tank and install it on the shaft as soon as possible. To prevent the bearing from cooling, The inner ring end face and the shoulder are not tightly fitted and can be axially tightened.

When the outer bearing ring and the bearing pedestal are tightly fitted, the method of heating the bearing pedestal can avoid scratching the mating surface. When cooking the bearing with a fuel tank, the bearing cannot be placed directly on the bottom of the tank. A grid should be placed at a certain distance from the bottom of the tank, or the bearing should be hung directly with a hook. In addition, a thermometer must be installed in the tank to control the oil temperature Not higher than 100 ℃ to prevent the tempering effect, which will reduce the hardness of the ferrule.

(3) Installation of tapered bore bearings

If there are an adapter sleeve and a withdrawal sleeve on the conical surface, the tapered bore bearing can be installed on the tapered journal. The amount of bearing radial clearance reduction can be used to balance the tightness. Before installation, the radial clearance of the bearing should be measured. During the installation, the consent should be measured regularly until the required clearance reduction is reached. Generally, a lock nut is used for installation, and a heating installation method can also be used.

(4) Installation of thrust bearings

The installation of the thrust bearing is relatively simple. First, the bottom shaft spring of the bidirectional thrust bearing is fixed on the shaft to prevent it from rotating on the axis. The fit between the inner ring of the bearing and the shaft is an interference fit, and the fit between the outer ring of the bearing and the bearing chamber is a clearance fit.

Wear is the most common problem in bearing housings, and bearing housing wear often occurs.

Repair method

Traditional methods generally use post-surfacing machining to repair, and surfacing will cause the component surface to reach a very high temperature, causing deformation or cracking of the component, and obtaining a size through machining results in a significant increase in downtime. The use of polymer composite materials for on-site repairs has neither thermal effects nor restrictions on the repair thickness. The abrasion resistance of the product and the concession properties of metal materials do not ensure 100% contact fit of the repaired parts and reduce equipment. The shock vibration avoids the possibility of wear. On-site repairs to avoid machining methods.

Repair process

There are generally only four steps:

(1) The surface treatment will require repairing the surface of the bearing pedestal to remove oil and moisture;

(2) Reconcile repair materials;

(3) Apply the material, apply the material evenly to the repaired part of the bearing pedestal , and fill it firmly;

(4) Wait for the material to solidify. The surface of the material can be appropriately heated to accelerate the solidification of the material.

General bearing room wear can be repaired in 3-6 hours, easy to learn, no special equipment and specialized training, compared with laser welding, cold welding, and other technologies save time and effort, the cost is only 1/5- 1/10, on-site repair reduces equipment maintenance time and transportation costs.

Copyright © Wuxi Spark Bearings Co.,Ltd Co., Ltd All Rights Reserved. Sitemap

www.spark-bearing.com. Profession in Roller Bearings, Ball Bearings and Taper Toller Bearings-China Suppliers.