News

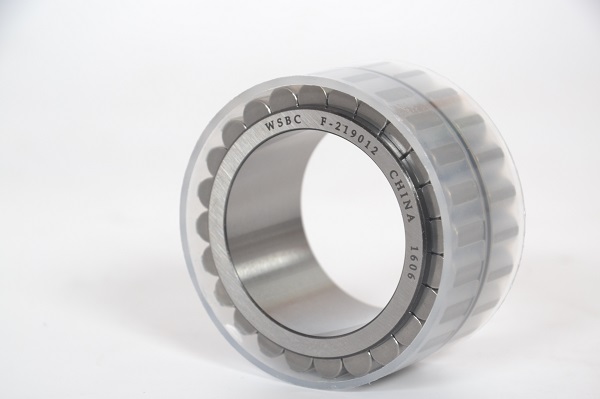

Analysis of Surface Roughness of Cylindrical Roller Bearing

Time:2020.05.25 Source:Roller Bearings Suppliers

In the grinding process of cylindrical roller bearings, the working surface is ground by a high-speed rotating grinding wheel, so if you do not operate and adjust the equipment according to the operation instructions during grinding, all kinds of roughness will appear on the bearing working surface Degree defect, which affects the overall quality of the bearing. Cylindrical roller bearings in precision grinding, due to the high surface roughness requirements, the grinding marks appearing on the working surface can often be observed with the naked eye. The main surface grinding marks are the following. (It is recommended to choose roughness detection: roughness meter) Bearings WSBC 22232CC/W33 online , pls click here :

Cross-helix marks appear on the surface

The reason for this trace is mainly due to the poor straightness of the grinding wheel and the unevenness. During grinding, the grinding wheel is only partially in contact with the workpiece. When the workpiece or the grinding wheel reciprocates for several times, the surface will reappear Spiral and visible to the naked eye.The pitch of these spirals is related to the speed of the workpiece table and the speed of the workpiece, as well as to the non-parallelism of the axis of the grinding wheel and the guide rail of the table.

1.The main reason for the formation of the spiral

(1)The dressing of the grinding wheel is poor, the corners are not chamfered, and the coolant is not used for dressing;

(2The guide rail of the workbench has too much lubricating oil, causing the workbench to float;

(3)The precision of the machine tool is not good;

(4)Excessive grinding pressure.

2.The reason for the formation of the spiral

(1)The rigidity of the V-shaped guide rail is not good, the grinding wheel is offset when grinding, but the edge of the grinding wheel is in contact with the working surface;

(2)The worktable commutation speed is unstable and the accuracy is not high when dressing the noisy wheel, so that the edge of the grinding wheel is slightly less trimmed;

(3)The rigidity of the workpiece itself is poor;

(4)The grinding wheel has broken and peeled sand particles and the iron scraps from the grinding of the workpiece accumulate on the surface of the grinding wheel. For this reason, the repaired grinding wheel should be rinsed or cleaned with cooling water;

(5)The dressing of the grinding wheel is not good, and there are local protrusions.

Fish scales appear on the surface

The main reason for the appearance of fish-like marks on the surface is that the cutting edge of the grinding wheel is not sharp enough, and the phenomenon of "gnawing" occurs during grinding, and the workpiece is caused by large vibration

The specific reasons for the appearance of fish scale marks on the surface are:

1.There are garbage and oil dirt on the surface of the grinding wheel;

2.The wheel is not trimmed;

3.The grinding wheel becomes blunt.The trimming is not sharp enough;

4.The diamond fastening frame is not firm, the diamond is shaking or the quality of the diamond is not good and not sharp;

5.The hardness of the grinding wheel is uneven.

Working face brushing

The main reason for the appearance of rough marks on the surface is that the coarse particles are caught between the workpiece and the grinding wheel after the coarse particles are dropped off.

The specific reasons for the workpiece surface being roughened during grinding are:

1.Traces left over during rough grinding, but not worn away during fine grinding;

2.The coarse and small abrasive particles in the coolant are not cleaned;

3.The abrasive grains are easy to fall off when the coarse-grained grinding wheel is just finished;

4.The material toughness validity period or the grinding wheel is too soft;

5.Improper coordination of abrasive grain toughness and workpiece material toughness.

Straight wave marks on the surface of the workpiece

We cut the cross-section of the vertical axis of the ground part of the workpiece and enlarged it, we can see that its periphery is similar to a sine wave. The center of the sine wave can be translated along the axis line without rotation, and the trajectory around the sine wave is the waveform cylinder, also known as polygon.

The reason for the straight waveform is the movement of the grinding wheel relative to the workpiece or the pressure of the grinding wheel on the workpiece periodically changes and causes vibration.This vibration may be forced vibration or self-excited vibration, so there is often more than one type of direct wave frequency on the workpiece.

The specific reasons for producing straight waveform traces are:

1.The clearance of the grinding wheel spindle is too large;

2.The hardness of the grinding wheel is too high;

3.The static balance of the grinding wheel is not good or the grinding wheel becomes dull;

4.Workpiece speed is too high;

5.The bearing of the grinding wheel spindle is worn, and the clearance is too large, resulting in radial runout;

6.Grinding wheel pressing mechanism or workbench "crawl", etc.

Burn marks on the surface of the workpiece

The surface of the workpiece is often burned during the grinding process. There are several types of burns. First, the burns are dark black patches along the grinding wheel processing direction;

The surface of the workpiece is burned during the grinding process for the following reasons:

1.The grinding wheel is too hard or the grain size is too fine, the structure is too dense;

2.Too much feed, insufficient supply of cutting fluid, and poor heat dissipation conditions;

3.The speed of the workpiece is too low, and the speed of the grinding wheel is too fast;

4.The vibration of the grinding wheel is too large, and burns due to the continuous change of the grinding depth;

5.The dressing of the grinding wheel is not timely or bad;

6.The diamond is sharp and the dressing of the grinding wheel is not good;

7.When the workpiece is rough ground, the burn is too deep, the amount of fine grinding is too small, and it is not worn away;

8.The clamping force or suction force of the work piece is insufficient. Under the action of the grinding force, the work piece may stop spinning.

So how do you know whether the surface of the workpiece is burnt during the grinding process? This can be checked by regular pickling. Bearings WSBC 22232CCK/W33 online , pls click here :

After the workpiece is pickled, when the surface is wet, it should be immediately visually inspected under the astigmatism lamp. The normal surface is uniformly dark gray.If it is a software point, it appears as a cloud-like dark black spot, and the perimeter is not fixed; if it is decarburized, it will appear as gray or dark black spots; if the grinding crack is processed, the crack will be cracked. The processing direction of the grinding wheel shows dark black patches, and the second is to show lines or intermittent lines.

If the above-mentioned burns occur during the grinding process, the reasons must be analyzed in time and effective measures must be taken to solve them to eliminate batch burns.

Hot Topics

Copyright © Wuxi Spark Bearings Co.,Ltd Co., Ltd All Rights Reserved. Sitemap

www.spark-bearing.com. Profession in Roller Bearings, Ball Bearings and Taper Toller Bearings-China Suppliers.