News

Precautions For Maintenance Life Of Tapered Roller Bearings

Time:2020.12.21 Source:Roller Bearings Suppliers

The method of determining whether the bearing disassembled can be used again

When judging whether the dismantled bearing can be used again, please check after cleaning the tapered roller bearing, carefully check the state of the raceway surface, rolling surface, mating surface, wear of the cage, whether the bearing clearance increases, and whether it affects the size Damage and abnormality with reduced accuracy. For non-separable small ball bearings, etc., use the one-hand flat-end inner ring and rotate the outer ring to check whether it is smooth.

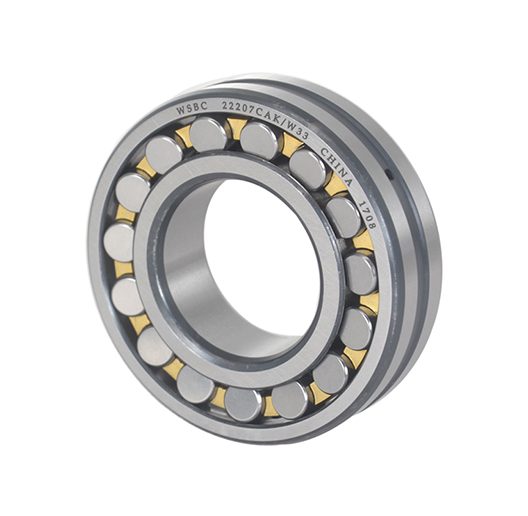

Separate bearings such as tapered roller bearings can be inspected separately for the rolling elements and the raceway surfaces of the outer ring. WSBC 22207 CA/W33 bearings online, pls click here :

Because large bearings cannot be rotated by hand, pay attention to check the appearance of rolling elements, raceway surfaces, cages, rib surfaces, etc. The higher the importance of bearings, the more careful inspection is required.

When judging whether the bearing can be used again, it should be determined according to the relevant factors such as the degree of damage of the bearing, mechanical performance, importance, operating conditions, inspection cycle, and so on. However, if the following defects are found during the inspection, the bearing cannot be used any longer and a new bearing needs to be replaced.WSBC 22207 CAK/W33 bearings online, pls click here :

Analysis of factors affecting bearing life

1.Lubrication conditions The viscosity forms a lubricating film between the rolling contact surfaces that is sufficient to separate the two surfaces. The lubricant must maintain a certain minimum viscosity at normal operating temperature to reduce bearing friction and increase bearing life. The influence of the average diameter of tapered roller bearing and the working speed. The viscosity of the working viscosity lubricant at the working temperature is determined by the viscosity at the working temperature t4℃ according to the viscosity-temperature curve and the viscosity ratio is an indicator of the ability to form the oil film. Factors such as have a great influence on the bearing life. When the operating condition becomes worse (temperature rises, the speed decreases, the amount of contaminants increases), the bearing life may be greatly polluted and the range will be reduced.

2.Calculation of WSBC bearing life correction factor and analysis method of influencing factors correction factor calculation method. Analysis of a basic factor that affects the correction factor of various bearing life, so that the bearing gets better lubrication conditions, should be greater than or equal to but the viscosity ratio It should not be too large, otherwise, the increase in viscosity may increase the working temperature of the tapered roller bearing. When the lubricant containing extreme pressure additives should be used, the pressure between the moving surfaces will also change the viscosity of the lubricant. The operating conditions (operating temperature, speed, load and size, and the effect of lubrication on bearing life are considered).

Wuxi Spark Bearing Co., Ltd (Aka Spark Bearings) is the complete, one-stop spherical roller bearings, supplier & manufacturer. All products are qualified and have passed the ISO 9001 qualification. Here are some popular types of spherical roller bearings, Send a quote and get the latest price of cheap bearings from Spark Bearings.

Hot Topics

Copyright © Wuxi Spark Bearings Co.,Ltd Co., Ltd All Rights Reserved. Sitemap

www.spark-bearing.com. Profession in Roller Bearings, Ball Bearings and Taper Toller Bearings-China Suppliers.